|

|

| Search | Car Forums | Gallery | Articles | Helper | Air Dried Beef Dog Food | IgorSushko.com | Corporate |

|

|||||||

| WIP - Street Post topics for any "Works In Progress" street vehicles projects in this sub-forum. |

|

Show Printable Version | Show Printable Version |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

#1

|

|||

|

|||

|

Building A 1/4 scale AMX 4 model

Dreams are always made of simple thoughts that you create in your mind and wish that the good ones will become a reality. This winter I am going to devote my own time, money and energy to create a 1/4 scale model of the AMX 4 that will be presented next September SoCal AMC Beach and Car show. Iíve been playing with this Concept 4 for a couple of years now and many my friends always ask why donít you just build it? Well I canít afford to build the real deal. However I can build the 1/4 scale that can always lead to a full runner. Attached are sketches, renderings and the start up a of a 1/4 scale model. Enjoy and let me know your thoughts. Its just sketches and a bit of clay that make up the work.

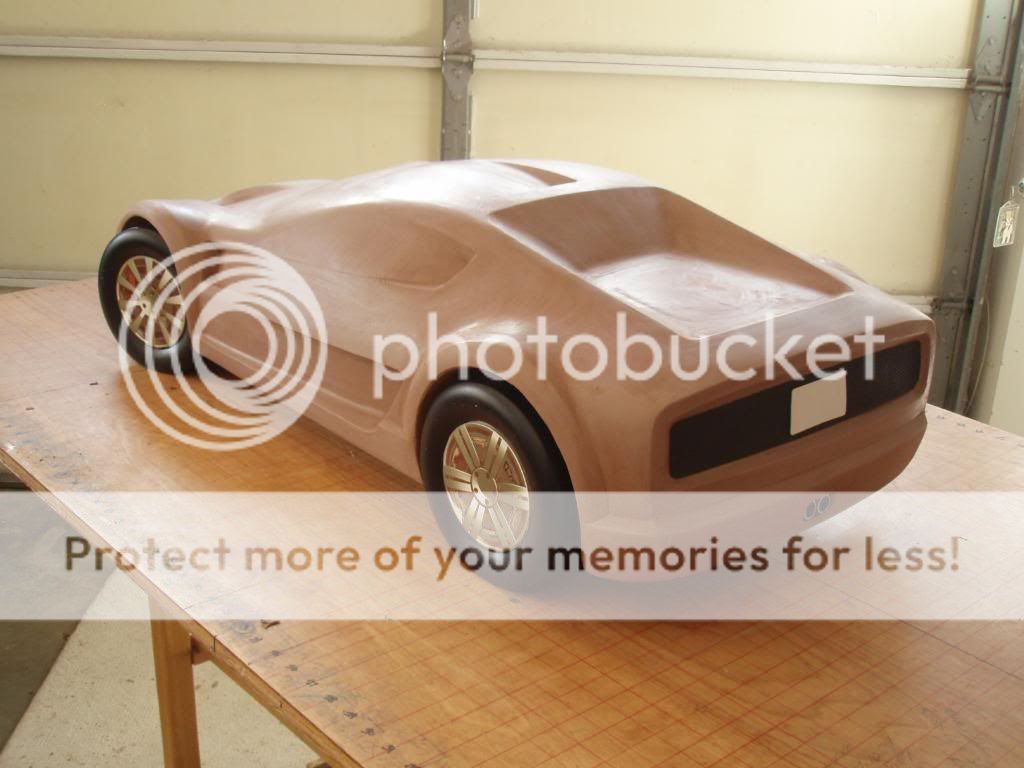

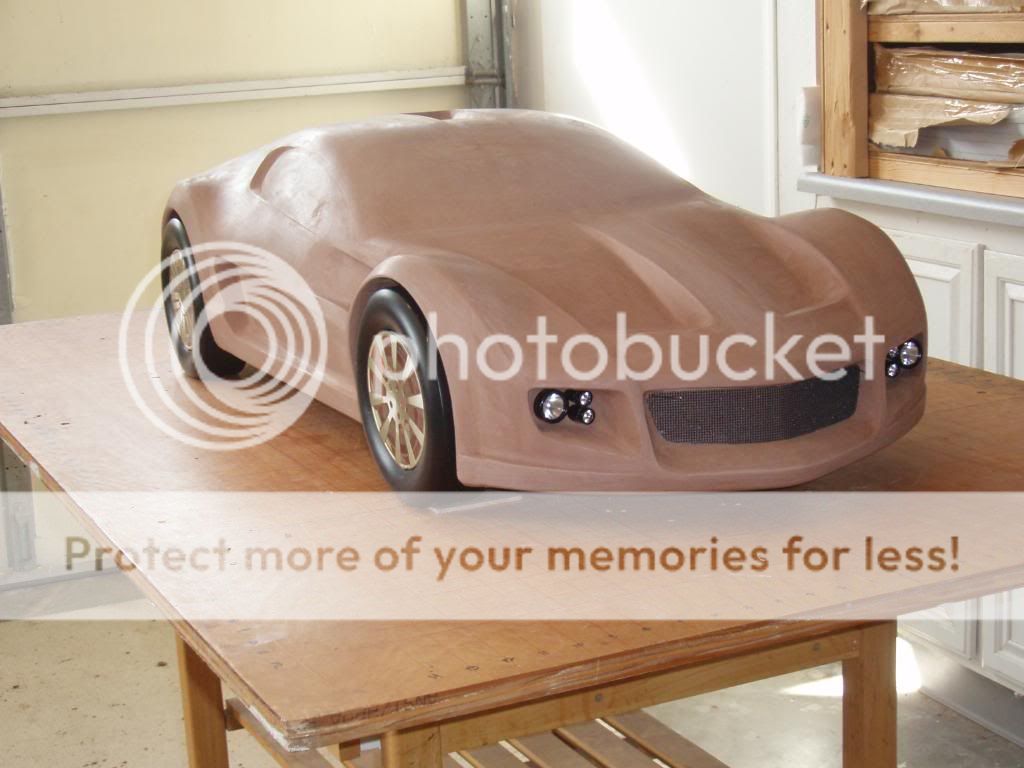

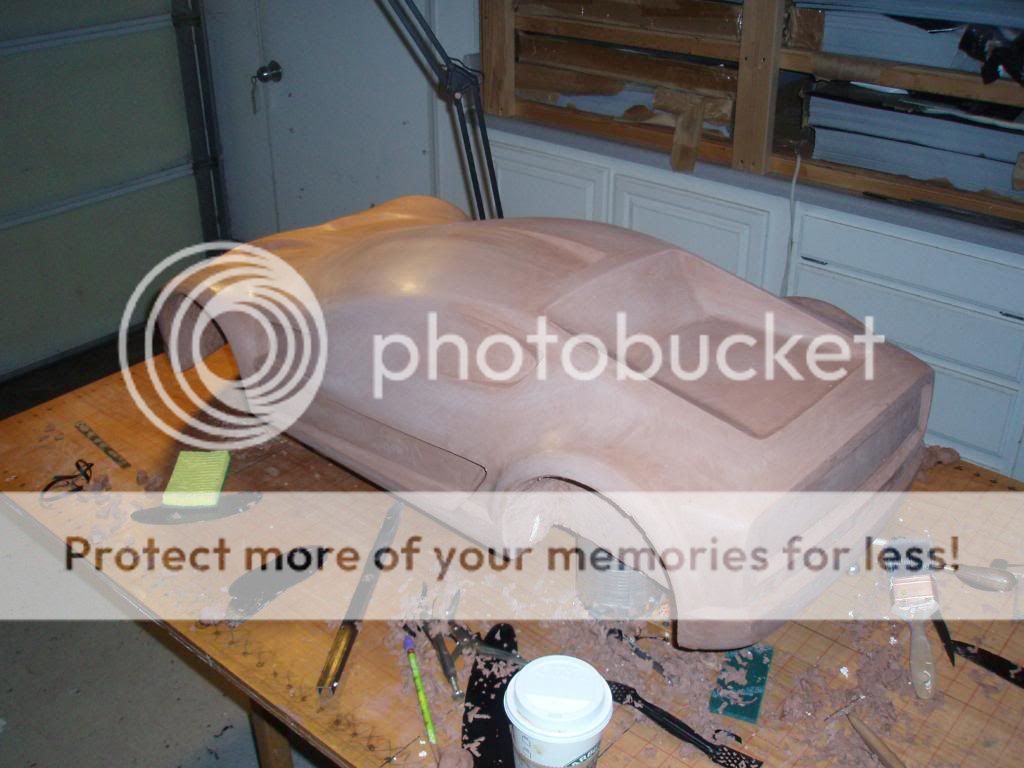

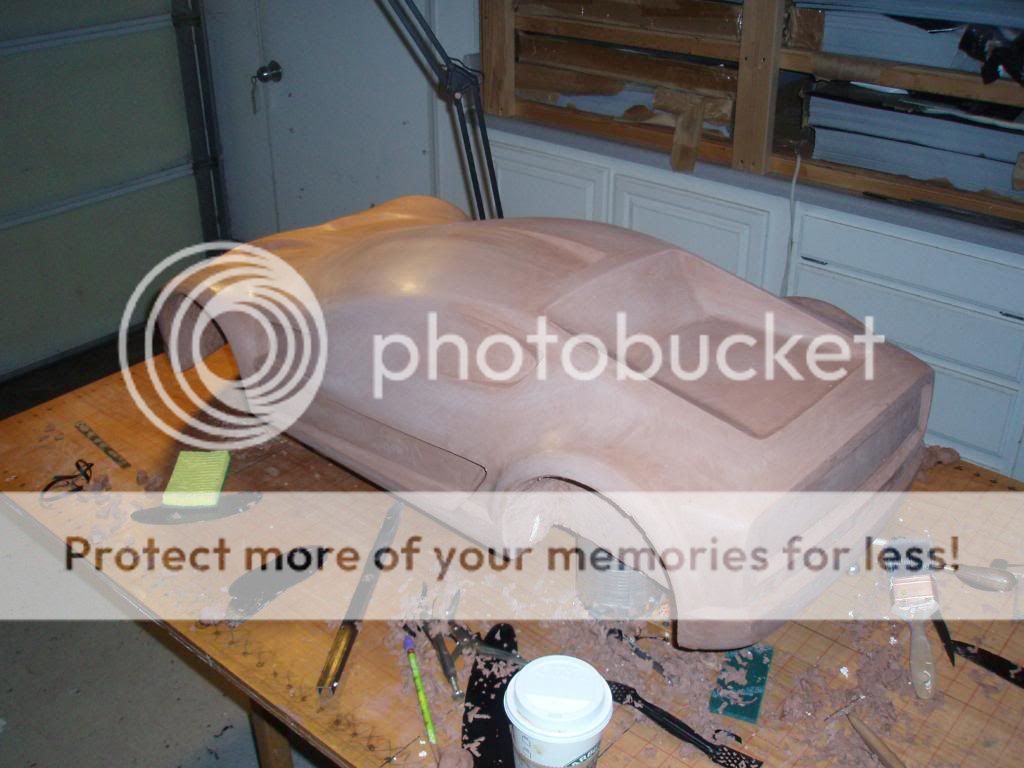

JTeague        Just a few shots of the Model in progress, Please go to www.socalamc.com for more details. Thank you 1. Had to get the studio// Garage into working order 2. Get one of my old clay models set up on the platform 3. Chop and channel        :arrow: Jan 29 2009 Sorry, Had to have a few days off, Got sick, Back to work with the AMX4. Getting the model cut into shape takes a few days but you also need to apply new clay to the rough surfaces of foam, You can get clay from this web site www.chavant.com Canvant clay is a stable way of holding surfaces, It dose not shrink or expand and is easy to work with. When heated it is very soft depending on the clays temperature. When very hot, It becomes very sticky and can burn your skin, When it cools down it becomes easy to shape into form. Chavant clay is what the OEM's have been using for years. 10. I had to build a small light oven for heating up the clay, Wood box with a heat lamp works fine for small jobs.   11. Still building some temps for sections on bodyside   12. Placing sections on bodyside to build out clay to surface and balancing, On a 1/4 scale model 3-5 section are needed.   Jan 30 2009 13. Still getting Package buck into shape. After reviewing these past photos, It might have gone just as fast starting with a new foam buck. Oh well, Live and learn. Plowing through it. Today was a good day however. Got the buck sized down and now I can start getting the clay into shape. Starting with the frt hood area and moving rearward.       14. I started to get the frt blocked in today and the next step is to get the Center line and roof blocked in this weekend. Next post update Jan 31 09 Feb 3 2009 15. Still taking steps in blocking the 4 in, Foam cutting and applying fresh clay to foam surfaces. When applying clay to the foam surfaces, The clay needs to be hot in order for the Clay to stick to the foam. Its real hot and very sticky.     I am working with Kelly Hullum, A student from More Park College, Great Guy and becoming a good friend! His dream is to become a designer. I am helping him get the basics together so that this fall he will be attending the Art Center College of design. I am helping him with the sketching, Rendering and the Design process that will help him acquire his goals and dreams.       Still a long way to go, The next step is the Balance between the 2 sides 16. Getting the 1 side blocked in 1st ( Drivers Side) is the best way to the start of the design refinments 17. You don't need to get every detail in at this point, Only the major surface block ins. Next update Friday the 6th Had a good day! Lots done and now its time to start blocking in the other side. This is done with just making a few temps and a little bit of good old Body filler ( Bondo) Kelly was a great help as well as my Daughter Nicole. They are both learning the skill of 3D model surface making. 18. make a quick template that is just a bit bigger than the surface that you want to copy 19. Use tin foil to clay surface to keep the bondo from sticking to the surface 20. Mix up a good batch of bondo and apply it to the template and the surface 21. Let it dry and pull it 22. Get sanding on the Template right away while the bondo is still setting up. Its just easy to cut the extra bondo off when it still a bit soft 23. Using the gride on the surface plate you can then transfer it to the other side for balancing left and right sides 24 Its best to make about 3-5 templates to get a balanced model            and of course the best little helper in the west "Rachel" my other Daughter  25. Now the fun begins, Designing surfaces. After just blocking in the right side, Its good to develop the left side and start balancing out the design lines. Its a bit of nip & tuck every surfaces until it starts to look good to your eye. I use black tape to hold lines, and use unique tools to shape the surfaces. I also use tin foil to look at high lights over the surfaces.         Next post // Next week! I need a day off Week 3 // Up date Feb 9 2009 Taking a bit of time off this weekend but I did manage to get a few strokes into the model. I'm starting with getting some air intakes into the body side and looking at front end and window graphics. Here are just a few images, I have to start dialing it in now with details and getting the other side up to speed in balancing.     Refine the design: Always reevaluating the surfaces and a continuation on the design development. This stage of the game is fun but time consuming. Each change now will effect the other side of the model so it's best to just concentrate directly on one side only at this time. Dealing with the other side is just a blank slate that should only have a semi close relationship to the designed controlled side. Kelly Hullum is still working hard and learning all the aspects of model building. This next week I am going to post up some of his images and drawing skills of what he has been learning during this time working with me. Yesterday I had the pleasure of working with Monique Tetreault, She is Victor Tetreault's Daughter who has recently Graduated from UC Irvine, She is also very interested in the process of building cars. This was her 1st time working in clay and I have to say, She did an amazing job working in this medium. Victor Tetreault and Martin Rodriguez are having there Grand Opening of V-Trac https://www.vtracauto.com/index.htm on March 22 in L.A. where I will be showing the Clay Painted Model of the AMX 4 for the 1st time. The next stage will be to take the Model and build 1/4 scale FRP (Fiberglass reinforced plastic)see through models for displays and also a few Signed and numbered limited versions for sale. The model will be displayed at the SoCal AMC September Car show. The next step is to use these proceeds and apply them directly into the build of a full running prototype.

|

|

#2

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

man thats insane i cant wait till its finished

__________________

|

|

#3

|

|||

|

|||

|

Re: Building A 1/4 scale AMX 4 model Update Feb 23 09

I'm Back! Sorry for the delay, I'm getting busy on other programs as well.....

Balancing is always the most time consuming part of building a clay model by hand, Pointing over the Driver side to the pass side. The next few slides will explain this process. Remember that the model is set up on a grid platform, This is where it really comes into play. I stated out by making sure that the model is on center line of the platform from Left to right and from rear to front. This is the only way to make sure that the model will be balanced from right side to left. Using an upright that is square the platform with the grids also assures that the model will get close in balance when building.    I use a U channel aluminum bought from any hardware store and sanded it down to make a fast tool for pointing over, I use the upright and set it to the design side for measurement to point it over to the other side.   I'll use Liquid paper to paint on the model where the tick marks have been made for indexing.       I then shave the surface down to the index points to get the balancing, Very time consuming but rewarding when getting it close The next step is to drag in sections to also get the balance from right to left. Notice that I have placed a rail on the platform, I will use this with a section and drag in a rocker and rear bumper section with hot clay to put in a quick rocker. Time setting it up is about 20 min, dragging it in about 5-10 min.    Next update March 1 2009 Hi There: It's been a long time from my last update. Time? Where does it go? Anyway here are just a few update snap shots. It's going to paint this next week. Details are still being made, Wheels and tires are next. Body to be finished by weeks end. Next time you will see the 4 is at the show. Hope you can make it JT   AMX 4 is now complete and ready for painting, Just thought you might enjoy seeing a unpainted clay model before it goes into the painting stage.

Last edited by JWTeague; 08-28-2009 at 08:15 PM. Reason: Up date |

|

#4

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

Interesting process. I'm looking forward to more.

__________________

SCCA 7, The lost Z Contest entry thread: Mystery? Beetle + Boxster = Bugster, P.T. Panel:click here Diablo Roadster: click here, & Porsche C2 Cab |

|

#5

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

Unbelievable project. Where did you learn (or dream up) this technique?

__________________

Mark R |

|

#6

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

That's awesome!!! Great reading and really fun to see. Keep up the good work and thanks for sharing.

|

|

#7

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

it's great to see how this sort of thing is done after having seen and marveled at so many of the 1/4 clay models.

__________________

AF's Guidelines Read them. __________________  Currently in the process of re-hosting my photos. If any go missing, drop me a PM. |

|

#8

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

Insane!

__________________

The client is not always right. - Enzo Ferrari ItalianHorses.net

|

|

#9

|

|||

|

|||

|

Re: Building A 1/4 scale AMX 4 model

Quote:

I've been in the business of designing and building the real deal for OEM's now for over 25 years and I've learned through very talented group of sculptors. They are all to be well respected for what they do for the automotive industry. I am not very good at it, I've just listened and learned how to do it. JT

|

|

#10

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

Amazing, impressive, fascinating, informative, unique and...addictive! I can't wait for more

__________________

Guideline for happy modeling: Practice on scrap. Always try something new. Less is more. "I have a plan so cunning, you could put a tail on it and call it a weasel" - Edmund Blackadder |

|

#11

|

|||

|

|||

|

QWIK Linerģ is a permanently bonded protective barrier between your vehicle and the outside environment, protecting your investment from rust, dents, scratches, and chemical corrosion. Unlike drop-in liners that promote payload slippage, and allow moisture and dirt to get trapped underneath causing rust and corrosion, QWIK LINERģ sets in seconds, conforming to every curve of your vehicle for immediately use. Extend the life of your vehicle and increase the NADA / Blue Book re-sale value with a real sprayed-on bedliner.

|

|

#12

|

||||

|

||||

|

Re: Building A 1/4 scale AMX 4 model

Having drooled over the AMX III at car shows for years I naturally had to see what this thread was about. Man! What a cool thread and not a computer in sight. Thanks for sharing all the details. I've been an engineer/devo guy in the industry for many years and have worked with stylists since the '80s. I never fully understood why it took so darn long to build/change the models. We would often show clown suits (half the vehicle next to a mirror) in the early stages when we needed to show multiple iterations quickly, avoiding all that symmetry work.

Last edited by CrateCruncher; 02-25-2009 at 11:40 AM. |

|

#13

|

|||

|

|||

|

AMX 4 Update August 2009

Hi There:

It's been a long time from my last update. Time? Where does it go? Anyway here are just a few update snap shots. It's going to paint this next week. Details are still being made, Wheels and tires are next. Body to be finished by weeks end. Next time you will see the 4 is at the show. Hope you can make it JT

|

|

#14

|

||||

|

||||

|

Re: AMX 4 Update August 2009

|

|

#15

|

|||

|

|||

|

Re: Building A 1/4 scale AMX 4 model

Sorry it's taking so long to get this finished, Got tied up with starting another project and I had to bench this for about 3.5 months. It's a go again and next is the painting stage of painting a clay model. After the SoCal AMC car show this September, I'm planing on making it into a fiberglass model and I'll go through the stages of making it into a FRP see through model. Thanks for all the support

Jeff Teague |

|

|

POST REPLY TO THIS THREAD |

|

|

|