|

|

| Search | Car Forums | Gallery | Articles | Helper | Air Dried Beef Dog Food | IgorSushko.com | Corporate |

|

#1

|

|||

|

|||

|

369 Holiday Project

I have been tinkering with the 369 engine in my car since our last endurance race back in August. We did a 4 hour race on a tighter track than we normally run on. We got a reasonable result running as high as 3rd and finishing 6th. Fuel strategy saw us drop from 3rd to 6th as we were just short of being able to run one stop for the race.

I was inspired after the race to add another 50 - 100hp to the cars top end after finding it just a little short on urge from 5000rpm on to dispatch GT3's and boosted Mitsubishi Evolutions down the shorter straights on the track. We had been running out of the box Edelbrock Victor Junior cylinder heads, an unported or port matched Edelbrock Victor Junior manifold and a 650 Mighty Demon carb. Compression with this combo was 10.4 and we were running high octane unleaded fuel (our 98 octane probably same as your 95?). The Victor Junior heads were removed and flowed prior to making any changes. Edelbrock claim these heads flow around 290 - 295cfm as supplied. We found mine were actually flowing around 260cfm so well down on factory numbers. These were then fully ported and fitted with 2.08 Ferrea valves. Heads then flowed 312cfm on the inlet at .600" lift and 220cfm on the exhausts at the same lift. We then flowed the heads with the Victor Junior manifold fitted. This dropped the cyl head flow from 312 back to 250cfm. An easy port was ported in the manifold and this brought flow up to 285cfm. At this point we decided to swap manifolds due ti the effort required to get the Victor Junior to flow the numbers we were looking for. We selected an Edelbrock Super Victor manifold which had a bigger runner size allowing the sorts of port taper that we were looking for after the ports were matched to the heads. While I would normally consider the Super Victor to be a drag race manifold not suited to the circuit there is an interesting twist here when it comes to big cube 8.2" deck smallblock Fords. This is evidenced when you compare a 351 Victor Junior manifold runner cross section of 2.7" with the 302 manifolds 2.1". Funny thing that the 302 Super Victor has a runner cross section of 2.7". Given I am running 369 cubes the Super Victor for the 8.2" deck engine is the equivalent of the Victor Junior for the 9.5" deck engine. The compression was also bumped up from 10.4 to 11.5 and I am swapping to running Avgas. To make the most of the better breathing I have sold the Mighty Demon and fited a Q750 Quickfuel carb. On a positive note with this carb, it required absolutely no adjustment to fire the engine and have it idle perfectly. This is a first for me on a race engine with a long duration solid roller cam so hats off to Quickfuel for thier calibration efforts. I will be very interested to see how that pans out across the fuel curve when we hit the dyno in the next week or so. Shot of new top end configuration with ported heads, Super Victor manifold and 750 Quickfuel carb:  The previous combo peaked at 466 RWHP around 6300 rpm. Will be going back to same dyno to set up the new combo and will post results when I have these. Should be a bunch of fun on the track as we have also gone to 3.89 ratio rear end as my local track has had a chicane put in on the back straight to slow the cars down. At the last big meeting there some late 60's/early 70's muscle cars were running 300kph down the back straight (all fitted with NASCAR engines)!! Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

|

#2

|

|||

|

|||

|

Re: 369 Holiday Project

Kel,

Thanks for the update. I'll be really interested in the curves before and after. Thanks also for the photo. That is one serious engine bay. I remain in awe of that header setup. Have you had any issue with the header longevity with them being wrapped? Are they internally thermally coated? I also noticed you have the upper frame rail wrapped. What prompted that? Does the header wrapping do anything for the cockpit temps? Hope you had a great Christmas and that you have a great New Year as well! Mike |

|

#3

|

|||

|

|||

|

Re: 369 Holiday Project

Quote:

I have wrapped the frame rail to reduce the impact of radiated heat on the wiring that runs down the frame rail. A couple of the header tubes are within an inch or so of the frame rail so the insulation would have melted off the wiring when the car is sitting still at race temperature. The car is not to hot inside Mike. We do not have the same ambient temps here to race in that you get in the US. We run a cooling vent to the driver and run drink bottles in the car and that works OK for us. Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

| The Following User Says Thank You to NZGTRA17 For This Useful Post: | ||

PanozDuke (12-27-2012)

| ||

|

#4

|

|||

|

|||

|

Re: 369 Holiday Project

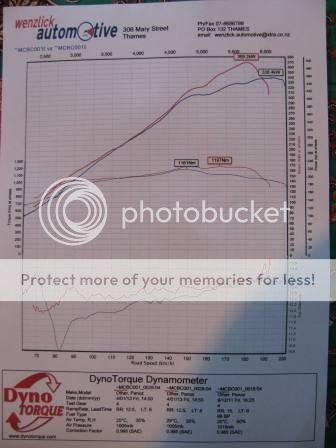

Finished up long day on dyno today. Power up from 466hp at wheels to 515 (602hp at flywheel) with mods as described above. No loss of torque down low, actually up slightly even with runs starting from 2500rpm.

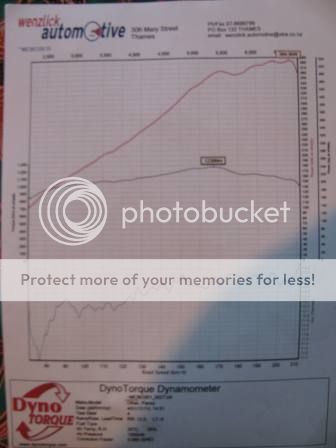

Following graph is with rev limit of 6300rpm. More power now at both bottom end and top end. Peaked at 580hp at flywheel. Both runs were to same rpm but on different graph scales so hence different rpm plots when overlayed.  Following graph is peak power run with rev limit of 6700rpm. Peaked at 602hp at flywheel.  Kel.

__________________

Kel M Panoz GTRA #17 New Zealand Last edited by NZGTRA17; 01-04-2013 at 01:24 PM. Reason: additional detail |

|

#5

|

||||

|

||||

|

Re: 369 Holiday Project

That's fantastic. Any side shots with those wheels on it? Did you fabricate that catch can? It's huge.

__________________

Brian B. Panoz GTRA - LS1 swap in progress #4 Z06 - NASA ST3/TT3 |

|

#6

|

|||

|

|||

|

Re: 369 Holiday Project

Quote:

Catch can is a Petersen unit. We have to run a 2 liter catch can here for larger displacement engines. I have mine set up with 2 x -10 breather lines going into the can and with a -8 line draining off the bottom of the can back into the sump. This has worked very well todate with little oil use/loss over 6 hour races. If I did the fabricating again I would use -12 lines off the engine and would remote locate the breather filter with a catch tray around it. Mine sits over the exhaust and in particular track conditions the odd drip of oil comes off the filter and drops onto the exhaust. Yes, pretty happy with outcome on the engine improvements. I have now achieved what I had set out to extract from the engine for what we are using the car for. More power could be easily squeezed out of the engine but that would require more rpm to the detriment of longevity for endurance use so future devlopement will focus on aero's and suspension. I have just picked up a 2 stage cooler pump for the diff so with this fitted with gearbox and diff coolers I can make the diffuser much more efficient by closing in the drive tunnel on the car. The development time spent on those areas will no doubt make me even more popular on the home front!! Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

| The Following User Says Thank You to NZGTRA17 For This Useful Post: | ||

Cobra4B (01-04-2013)

| ||

|

#7

|

||||

|

||||

|

Re: 369 Holiday Project

Nice work!

I briefly ran my GTS at 520RWHP. I think maybe 2 races and one weekend. Felt the chassis was not enjoying all that power. Will be interested to see if you feel the chassis needs reinforcement or not and if you start breaking more parts. All I need to do is install a 650cfm carb (up from the 390cfm currently) and I pick up 100hp. So, Kel you might make me jealous enough that I have no choice :-) I will tell you that the 997's are in for it with your new power. Dan and I were monsters the weekend we turned her loose.

__________________

Brian G. 2000 Panoz GTS #420 NASA ST1 427ci Stroker

|

|

#8

|

|||

|

|||

|

Re: 369 Holiday Project

Quote:

Not sure the chassis will be as much of an issue for me compared to your car Brian. We are doing most of our miles on DOT's so not the same lateral or traction loads as with your large slicks. I do have some 280/680/18 slicks on the car to try now though so will be interested to see how the car feels on those. Would love to see your car run at Daytona with the 650 carb fited Brian. That would really give the NASCAR type cars and the Vipers something to think about.....!! Will keep you posted on how lap times go with increased power. May be a quiet year on the racing front as we are contemplating a road trip in the States possibly during the endurance season over here. Will see how it pans out. In the meantime, put your hammer down for a wile, dust off that 650 carb and go Viper hunting......... Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

| The Following User Says Thank You to NZGTRA17 For This Useful Post: | ||

feqrags (01-05-2013)

| ||

|

#9

|

|||

|

|||

|

Re: 369 Holiday Project

Kel,

If you work out the trip, we'd like to hook up if it isn't out of your way and you have the time. Just NW of Houston. Tom (Cobrafang) is just outside of Augusta, GA, his car has Kelinator headers and exhaust on his 347. If you're all booked up, no problem. One of these days we might all be fleeing to Kiwi country to get away from the useless idiots in charge here! Mike |

| The Following User Says Thank You to PanozDuke For This Useful Post: | ||

Cobra4B (01-11-2013)

| ||

|

#10

|

||||

|

||||

|

Re: 369 Holiday Project

Do let us know if you're going to be in the states.

__________________

Brian B. Panoz GTRA - LS1 swap in progress #4 Z06 - NASA ST3/TT3 |

|

#11

|

|||

|

|||

|

Re: 369 Holiday Project

Quote:

Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

|

#12

|

|||

|

|||

|

Re: 369 Holiday Project

Will do Brian.

Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

|

#13

|

|||

|

|||

|

Re: 369 Holiday Project

Is someone out there offering cross-over headers for the GTS? That NZ set-up looks to be very nice.

|

|

#14

|

||||

|

||||

|

Re: 369 Holiday Project

No... Kel made those himself.

|

|

#15

|

|||

|

|||

|

Re: 369 Holiday Project

Quote:

I have always used exhaust tuning to assist with achieving the desired power spread as well so this was another factor in building a custom setup. If you chose to go down this route it will take between 40 - 80 hours to fabricate depending on experience level and tooling that you have available. I used a set of fabricated header plates that had the first 2" of primary already welded in. I highly recommend that as it saves lots of time and gives you a great base to work from. I also recommend TIG welding the headers if possible. Relatively easy and produces great results. Finally if you build a set have them coated as this will prolong the headers life........I am in no hurry to build a new set!! Happy to supply the mathematical calculations I used for my set if you head down this path. Kel.

__________________

Kel M Panoz GTRA #17 New Zealand |

|

|

POST REPLY TO THIS THREAD |

|

|

|