|

| Search | Car Forums | Gallery | Articles | Helper | AF 350Z | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|

#76 | |

|

Geo Metro Lover

Join Date: May 2005

Location: Eastern Washington State, Washington

Posts: 1,622

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

This is not a Lead (Pb) gasket!

I found the Federal-Mogul Web Site http://www.federalmogul.com/en/OETec...derHeadGasket/ and they sell Steel backed Head Gaskets with Silicone covering. I put a strong magnet on my FEL-PRO HeadGasket and it stuck to it hard. So this is a steel gasket with some sticky feeling, rubbery backing on both sides (Silicone?) That must be the Permadry or Permadry Plus backing. "PermaDry gaskets, made of molded rubber, are excellent as replacement parts on engines that were originally equipped with molded-rubber gaskets. PermaDryPlus gaskets have a rigid carrier and molded-silicone rubber sealing bead. They are designed and built specifically to seal difficult problem leaks." So I suppose all I need do is clean and dry the two surfaces and use no gasket material....(?) I cannot find any instructions - even on the web site! How Dumb... Who is dumber - me or them!? DoctorBill PS - just got a brainstorm and called the Head Repair place I used...talked to The Man... He said, "Use nothing. Place it dry between the Head and Block and screw the head on. The rubbery stuff melts into place. Thats all she wrote." Got my answer....

__________________

|

|

|

|

|

|

|

#77 | |

|

AF Enthusiast

|

Re: NOT the end of my '93 metro...Life after death! RINGS

Ring end gap in this engine should be measured about 2 1/2" down from the top of the block. This is where you cover all your bases rather than measuring at varios locations in the tapered area of the cyl.

I searched for instructions also without success. Maybe your gaskets came in a white box without labeling that machine shops often use because they are much more economical. Same quality different packaging. Fel-Pro brown boxes with red and blue labeling have helpful instructions... that many people never read. Anyone who has not heard of TTY needs to learn. Over the past 25 years TTY has become more and more common. For the past few years more engines than not use TTY head bolts and specs. It is not uncommon that someone torques to the torque spec without adding the additional degrees that the spec calls for because they have never heard about TTY. Obviosly problems will follow for those individuals. Looks and sounds like you have a PermaDry Plus head gasket. As Doc learned the head bolts should not be re-torqued. Torque the head bolts to the correct spec, the end! That will work. If the manufacture has changed to TTY specs on later years of the same engine, following the update TTY specs is an upgrade that has been proven by the manufacture to be advantages. I have not found a TTY spec for this engine, yet I suspect there are newer specs for the head bolts than the Chilton Repair Manual. The examples given in my earlier post were examples, not instructions to follow. The torque and additional degree specs are provided by the manufacture. Instructions vary for each application, they are not just guessed at. The additional degrees do not dramaticly increase torque beyond the torque only spec because the bolts stretch. Here are a couple of links explaining Torque-To-Yield. http://www.canadiandriver.com/articles/jk/040303.htm http://www.robbos.com.au/myweb/Tech_Bolts.htm Last edited by JustSayGo; 09-12-2006 at 03:46 PM. |

|

|

|

|

|

|

#78 | |

|

AF Enthusiast

Join Date: Jul 2003

Location: Detroit, Michigan

Posts: 1,307

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

Ahh good Bill

Weird, usually silicone coated gaskets have rubber seals around the water jacket holes. The silicone gaskets are very common nowadays. Anyways, on to orientation of the gasket.. The dowells that were in the block that are used to line the head up with the block are in the top left, and lower right of the block. The headgasket has larger holes to slide over these hollow dowells. You cannot put the gasket on any other way when you have the dowell pins in the block. If that doesn't make sense, this will Weird, usually silicone coated gaskets have rubber seals around the water jacket holes. The silicone gaskets are very common nowadays. Anyways, on to orientation of the gasket.. The dowells that were in the block that are used to line the head up with the block are in the top left, and lower right of the block. The headgasket has larger holes to slide over these hollow dowells. You cannot put the gasket on any other way when you have the dowell pins in the block. If that doesn't make sense, this will  It's pretty simple when you look at the shape of the gasket and the block. It's pretty simple when you look at the shape of the gasket and the block. |

|

|

|

|

|

|

#79 | |

|

Geo Metro Lover

Join Date: May 2005

Location: Eastern Washington State, Washington

Posts: 1,622

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

Ha Ha! I did not think to take the Head Gasket outside and compare it to the

engine block. Yes - would have been obvious....duuhhh...! Not following something you wrote....Everything else makes splendid sense. "The dowells that were in the block that are used to line the head up with the block are in the top left, and lower right of the block. The headgasket has larger holes to slide over these hollow dowells. You cannot put the gasket on any other way when you have the dowell pins in the block. What dowels are you talking about? Are there supposed to be some type of short rods that I lost track of...? When I had the Head Rebuild returned to me, I got a bag of screws and things and there were two short pieces of "pipe" in the bag. They are 0.688 inch long by 0.50 inch in diameter - look like they were yanked out with pliers - ends chewed up. What were those from ? So now I know how this is to be situated. Seems to me that some of the "holes" in the gasket don't match the head or block all that well! Doesn't help water flow rates and oil flow rates! Two holes don't have corresponding holes in the Head. Upper left and lower right in your retouch of my photo. Also, why the metal ring around that one hole? I think maybe someone answered that before....?  I just bought a spray can of "KLEAN STRIP" Premium Stripper to try on the oil pan and intake manifold goo that is stuck to them....Hope it works! I will try it on some ALUMINUM FOIL first! Also bought a tube of "AUTOMOTIVE GOOP" for the pan gasket. Package says it is "Amazing". (Glues whatever- bonds forever) We will see what we will see..... - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - An experiment for all of you to try - If anybody out there has some old solid powdered Drain-O or some solid or liquid LYE - put about a half of a shotglass of liquid lye in a shotglass. If you have the old solid Drain-O, pick 20 of the white crystals out and drop them into the shotglass - add tablespoonful of water - mix with a SS spoon. Wash your hands off! Gets very hot. Ball up a postage stamp sized piece of Aluminum Foil and drop it into the lye. Stand Back! Wait.... Lots of action soon! Light a match & hold it over the shotglass. Keep kids away! The spray can blind you or them....hot lye is hideously dangerous. THAT is what would happen to an Aluminum engine block if lye or Oven Cleaner gets on the block... When it is all over, pour it down the drain along with plenty of COLD water. Don't get the liquid on your hands....Vinegar will neutralize it if it gets on you...! DoctorBill

__________________

Last edited by DOCTORBILL; 09-12-2006 at 08:54 PM. |

|

|

|

|

|

|

#80 | |

|

AF Moderator

Join Date: Oct 2004

Location: Bellingham, Washington

Posts: 1,751

Thanks: 0

Thanked 73 Times in 73 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

the Pipe things fit into the block to hold gasket in place while you put head on, if one end is chewed up put that end into the block, as long as they aren't loose they should be fine. they fit into the 2 end head bolt holes that are by the long slot water passages. the screw looking thing in the block is a oil restrictor for the head. thats why it has the extra boss around the gasket so it doesn't leak

|

|

|

|

|

|

|

#81 | |

|

Geo Metro Lover

Join Date: May 2005

Location: Eastern Washington State, Washington

Posts: 1,622

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

I almost tossed those two pipe things away....thought they were something

from inside of the Head that was replaced during the rebuild. I don't remember them protruding when I took it in to the Head Shop.... Do I actually need them? Are they required for "registration" of the Head and Head Gasket? If so, I can dress them up with a file to remove the gashes in them that the Head repair Shop made taking them out - with gas pliers?  Or should I try to purchase new ones? Odd that he didn't tell me about them when he returned the rebuilt Head...! I will call him tomorrow and ask why they returned them so boogered up! I would have to do a lot of filing to dress them up to where I'd trust them. They fit into any of the four holes at the corners of the Head. (Picture)  Is this important? DoctorBill

__________________

Last edited by DOCTORBILL; 09-12-2006 at 10:26 PM. |

|

|

|

|

|

|

#82 | |

|

AF Moderator

Join Date: Oct 2004

Location: Bellingham, Washington

Posts: 1,751

Thanks: 0

Thanked 73 Times in 73 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

put them in the BLOCK. as long as they will tap in with the grip marks down they will work fine, yes you need them to hold the gasket in place on the BLOCK as you set the head on. will also align the head to the block properly. the part were they removed them will be below the block surface and as long as they are snug in there will pose no problems

|

|

|

|

|

|

|

#83 | |

|

Geo Metro Lover

Join Date: May 2005

Location: Eastern Washington State, Washington

Posts: 1,622

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

OK - here is what I did.....BTW - Chilton says zip about the little pipe boogers!

Does oil or coolant pass thru these little pipe boogers? I do not want to "tap them down into the head" because I am an anal retentive, obsessive compulsive, perfectionist pekkerhead.... So, using a little trick I learned by watching several mechanics work (when I was a teenager), I used a file to clean up the gashes in the 1/2 pipes and then coated them with Black "Sharpie" Permanent Marker Ink. I then tried to fit them into one of the four corner holes. I looked at the inked end area and filed on that part where the ink was gone (rubbed off by the hole's wall) and tried again (after reinking the filed area). The areas where the ink is rubbed off got larger and larger until the unit fit into the hole. The ink trick tells you where you need to file! In that way, I got the little boogers to fit in the holes again..... What are these two pieces of pipe referred to as? Calling them "Little Pipe Boogers" is probably not acceptable to the sensitive individual. Why did the Head Service treat them so shabbily? At least they returned them - I would not have known about them if they hadn't... DoctorBill BTW - Watching other people work has several rewards. It is pleasant because it is not you having to do it, it is educational in that you learn things useful in your later life - if you are smart enough to pay close attention and bug the shit out of the worker by asking those questions! Just beware - some people resent the questioning....

__________________

|

|

|

|

|

|

|

#84 | |

|

AF Moderator

Join Date: Oct 2004

Location: Bellingham, Washington

Posts: 1,751

Thanks: 0

Thanked 73 Times in 73 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

if they were stuck in the head they had to pull them out to surface the head. if you put them in the right holes on the block nothing other than a head bolt goes through them. the factory puts them in tight enough that they need to use a pair of vise grips to remove them. they are called locating dowels. if you put them back in the block they keep head gasket from sliding around as you set head back on, if you put them in the head the gasket on the top of the block will slide around as your trying to line head up. if i pull then out i always put the side i used pliers on down into the block, if they are to loose and wobble a bit i spread them with a screwdriver

|

|

|

|

|

|

|

#85 | |

|

AF Regular

Join Date: Feb 2004

Location: Alton, New Hampshire

Posts: 239

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

DoctorBill, Since you are a long time poster, I feel like I've gotten to know you a little bit. Again, you are worrying about the smallest details here. There is a lot of interest in this post because you are doing the whole job and documenting it so well along the way....but please, lets get on with it! You need to spend less time typing, and more time getting the pistons installed, the pan back on, the head back on...etc. I want to know how well it will run! I feel like a kid waiting for Christmas as I check the post daily to see how it's progressing....And, I can't believe you're doing this all outside! Wow!

|

|

|

|

|

|

|

#86 | |

|

Geo Metro Lover

Join Date: May 2005

Location: Eastern Washington State, Washington

Posts: 1,622

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

You know - I was wondering when someone would get on here and tell me to

get off my dead arse and Finish The Job Already! This is scary stuff! If I screw up, I will lose the ~$400 I have into this already, plus, the car will be dead meat after all the other money I have put into it. Besides....Please sing along with me folks..... "I beg your pardon! I didn't promise you a rose garden......" I feel like the guy who is walking thru a minefield and everyone is yelling, "Go on! Don't worry - be happy! No sweat! I'll follow your footsteps!" Hey all you folks waiting on me, start a thread yourself! Take digital photos. Am I the only person around? Let's see how brave you are! A mechanic I ain't.......like to be, think I can be, but I ain't. Having given my excuses - I finally honed the cylinders today..... and like everything else about this job, it was no sweat - I worried too much. Here are the pictures. I bought a "bath scrubber" thing at Wal-Mart for cleaning out the cylinders. It worked like a charm - conforms to the cylinder walls nicely and is very soft.  Notice all the adhesive around the intake manifold (white arrows) from someone else's work. Bought a can of spray paint remover for that.  Here is what my honing setup looked like when completed. I put the honer in a plastic bag immediately to keep grit off of it. $22 for 60 seconds of use.  I honed up and down quickly for a slow count of 20. Here is what the cylinders looked like after I honed. Looks like the very center of the #1 cylinder was worn the most and got the least honing marks....  Here is a close up of Cylinder #1 That cylinder (#1) seems to have worn more on the right side than on the left side (facing the engine). The honing pattern is more complete on the left side. Is that normal?  Cylinder #3  I cannot tell if the proper "Cross-Hatch" pattern is there or not. In any case, I wouldn't know how to change it anyway! I went up and down rather fast to make the pattern...(?) I believe that if one had a really slow drill (50 rpm?) that one could get those 30° crosshatch patterns, but with a fast drill (high rpms), I don't see how one can do it....anybody? And here is the registration hole for one of those two small pipe pieces. The pipe fits in nicely. Looks like water moves thru it.  The wind is blowing today and Milkweed seeds are stuck to all the oily surfaces! Looks like its going to rain soon. Oh boy! Is this fun, or what!? Like Russian Roulette... Actually, if this works, I will feel like Superman and Albert Einstein all rolled up into one. But I will worry every day that something will go sideways and the engine will explode at 55 mph on me. Its the way I am. Go figure! Next - I will put the rings into the cylinder and measure the gaps. Then I want to clean the Carbon out of the EGR passageway of the Intake Manifold all the way to the EGR valve. I have a "Pull-n-Save" EGR valve that I previously cleaned out (A thread with photos on the Forum). I am in no hurry - I have my '91 Jeep Cherokee 4x4 and it won't snow for 2 to 3 months (knock on wood). I start my Chem class monday (18th) with 50+ students. Labs and quizzes to grade coming up. I am having a nervous kind of fun with this.... DoctorBill

__________________

Last edited by DOCTORBILL; 09-13-2006 at 05:09 PM. |

|

|

|

|

|

|

#87 | |

|

AF Enthusiast

|

Re: NOT the end of my '93 metro...Life after death! RINGS

BTW - Watching other people work has several rewards.

It is pleasant because it is not you having to do it, it is educational in that you learn things useful in your later life - if you are smart enough to pay close attention and bug the shit out of the worker by asking those questions! Just beware - some people resent the questioning.... Often times the worker is annoyed because they don't really know why. I need to know why because my memory works better when I know why. I find the details interesting. Ignorance of details and not asking why before assembly, will sometimes or eventually always result in wondering why later, when the engine doesn't run as well as expected or worse. The reason the machine shop wasn't more careful about removing your index guide tubes is because the mechanic is supposed to know and remove them. Somewhat experienced mechanics leave them in because they don't notice them or don't want to spend their time removing them, or are inconsiderate and expect the machine shop to have the correct tool to remove them without additional charge. The tubes could have just as easily stayed stuck in the block rather than the head. Solid dowels are just as common. While watching and asking why at a machine shop I have heard machinists comment about the dowels not being removed by the mechanic and then surfacing the head without removing the dowels and returning the rebuilt heads for the mechanic to spend time removing the dowels by drilling them out and locating new dowels. It is all about teaching the mechanic (who probably tried to tell the machinist how to do his job at some point in the past) a lesson he will never forget. Maybe because of that opportunity, I look at and remove the index tubes or dowels. There are circumstances when both parts being assembled will have dowels or tubes. That won't work either. Your tubes can be straitened filed and ugly end put into the block as Crvett69 wrote. Your tubes do not have oil or water passing through them. Bolts go through the tubes. The "what is this question" you asked on the head gasket picture, I think is where the oil goes into the head for the cam bearings. |

|

|

|

|

|

|

#88 | |

|

Geo Metro Lover

Join Date: May 2005

Location: Eastern Washington State, Washington

Posts: 1,622

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

Sitting here reading your response and eating Oatmeal cookies with fresh coffee.

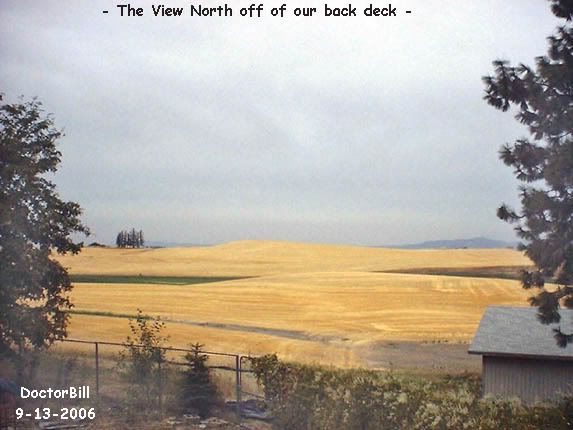

No Boss telling me to hurry up and finish (except you folks!). Nice..... Being semi-retired has certain advantages.....having lots of money is not among them....... A comment on learning and watching - Ignorance is expensive! These "index guide tubes" or "Locating dowels" - where does one obtain them? Have not seen them for sale anywhere. Mine are OK now after about 45 minutes of dressing them with a file as I previously described. If you will go back to my posting about the honing job and look at the second picture where the bath scrubber is in the #3 cylinder, you will see on the far left of the engine block a small hole second up from the bottom. I looked closer today and noticed that it has a Brass cat's eye slot in it and a ball bearing underneath that slot. Is that some type of "one-way valve" for something? Does Oil or water go thru it? Just curious.... Going out to measure the Ring Gaps soon. Blowing like mad - does that before a storm front comes in. Love it - crap gets into everything. Dirt... This is wheat country. They are disking now and dust, pollen and dirt are in the air blowing in clouds. Nothing can stay clean. All my vehicles look like a bucket of dirt was thrown on them. A big bird crapped on my cement parking pad as if a Hippopotamus dumped there! Must have been a huge bird - looks like a quart of bird dump hit the driveway! Come live in NorthEastern Washington State!  Those are Wheat Fields.  Wheat fields in the distant hillsides. DoctorBill

__________________

Last edited by DOCTORBILL; 09-13-2006 at 06:34 PM. |

|

|

|

|

|

|

#89 | |

|

AF Moderator

Join Date: Oct 2004

Location: Bellingham, Washington

Posts: 1,751

Thanks: 0

Thanked 73 Times in 73 Posts

|

Re: NOT the end of my '93 metro...Life after death! RINGS

if your really that worried about the locating guides i will pull you a good set and send them to you. like i said before the thing with a slot is the oil feed hole for the head, the check ball keeps it from draining back out when you turn engine off

|

|

|

|

|

|

|

#90 | |

|

AF Enthusiast

|

Re: NOT the end of my '93 metro...Life after death! RINGS

You are the boss DoctorBill. The scrubber looks great. Maybe an even better tool is a new toilet bowl brush from the dollar store. Your cross-hatch honing looks good. Your correct, even slower turning speed would be better. The flex hones with the balls would have looked better in that you wouldn't notice any low spots in the cylinder. Looks aren't everything... in this case. As written by somebody in an earlier post strait stones leave a straiter cyl. and straiter is betterer.

Don't worry. You will soon be confident that your masterpiece will not blow-up even at 90mph. Good idea useing the marker. Did they have markers way back in those days? JK! I remember a bit of shock the first time I saw a red marker when I was about six or seven years old after only seeing black ones. There is risk with rebuilding as any other repair. There is risk buying and installing used engines, machine shop rebuilt, or brand new. The brass thing could be a check valve, Does the ball push against a spring? If not it must fall under, "or something", some type of plug used after machining an oil galley passage. Locating dowels could be difficult. The dealership might not stock them. The machine shop is the best bet. |

|

|

|

|

|

|

POST REPLY TO THIS THREAD |

|

|

|