|

| Search | Car Forums | Gallery | Articles | Helper | AF 350Z | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|||||||

| Fiberglassing Fiberglasssing explained and the proper techniques on working on a fiberglass project. |

|

Show Printable Version | Show Printable Version |  Email this Page | Email this Page |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

|

#1 | |

|

Banned

|

PVC & Polyester Resin

Just a quick qestion.

Does Polyester Resin weaken PVC as far as how much pressure it can hold? That is my main concern. I need the pressure capeability of sch80 or sch120 but it is almost unlocatable or extremely expensive in my area. And because this isnt a "profesional" job (building a hybrid potato gun which will be remote fired, hopeing to break 700f/s with lemons) i figured the combustion hcamber an couplings could be fiberglassed over with 6 or so layres of mat and 3 layres of cloth and bondo and painted for a smooth look instead of the old PVC look. My only conern is if it weakens the PVC then i am relying completely on my no so perfectly refined Fiberglassing skills to hold back perfect a/f mixtures of air and propane at 2 and 2.5atm being detonated. |

|

|

|

|

|

|

#2 | |

|

Captain Over Engineer

|

Re: PVC & Polyester Resin

The bondo to smooth it out isnt a good idea. The PVC chamber, and the barrel quickly expand an shrink while the bondo wont. It will crack and break off.

The fiberglass wont do much either. Except when it explodes fiberglass shards will go everywhere. What are you using for propellent?

__________________

-Mike AF Director of Media / Photographer  mike.lawrence@automotiveforums.com | AutomotiveForums.com | Flickr Gallery |

|

|

|

|

|

|

#3 | |

|

Banned

|

Re: PVC & Polyester Resin

Propane. or MAPP gas. ill start with Propane and if i find it to fall short of 700f/s then ill try MAPP gas. for regular firings it will be Propane becaise it is alot less expensive compared to MAPP gas.

|

|

|

|

|

|

|

#4 | ||

|

Captain Over Engineer

|

Re: Re: PVC & Polyester Resin

Quote:

Being that the fuel will be in a closed area, the oxygen will be limited. Propane can displace oxygen. For proper explosion you need three things, air, fuel, and a ignition source. Without the proper air/fuel mix you will have problems detonating it correctly. You will need to calculate how much oxygen, and how much propane need to be introduced into the firing chamber. Propanes UEL (upper explosive limit is) 9.5, and its LEL (Lower Explosive Limit) is 2.2. That leaves 7.3% room for error in the mixture. You'll need to figure out a lot of math, and a way to properly measure how much oxygen and how much propane to use. You will also need a stir for the air/fuel since the air will easily be displaced by the fuel, and the two will seperate. I cant tell you how to make it, but I can tell you what wont work.

__________________

-Mike AF Director of Media / Photographer  mike.lawrence@automotiveforums.com | AutomotiveForums.com | Flickr Gallery |

||

|

|

|

|

|

#5 | |

|

Forunn Daberator

Join Date: Mar 2004

Location: bumblefuck, Texas

Posts: 10,590

Thanks: 363

Thanked 364 Times in 309 Posts

|

Re: PVC & Polyester Resin

Oh I do love the fiberglass shitter at the bottom of the page.

You can infact reinforce pvc with an outter coating of fiberglass. And polyester resin will not weaken the pvc. I would suggest not building it out of pvc though. You can build it out of steel pipe (or cast iron would work fine also) for about the same price. If you really want to get a bang out of it you can use... well your the genius I'll let you figure your plan out.

__________________

|

|

|

|

|

|

|

#6 | ||

|

Banned

|

Re: Re: Re: PVC & Polyester Resin

Quote:

as you should know, assumeing O2 levels in the air are truely 21% 4.03% is the ammount needed for a completely ballenced reaction iwth no limiting factors giving way to the most powerful charge. MAPP gas is extremely close at 4.05% i beleive. C3H8 + 5 02 => 3 CO2 + 4 H20 and because 1mol of all gasses is the same vomlume at STP (and because we arent operating out gun all that far away form STP) Propane:Oxygen ratio is 1:5 or 20% 20% of 21%= %4.2 it doesnt take a LOT of math. you can vary the Pressure which you raise the combustion chamber to (this is a hybrid, using presurized charges at 1,2 and 2.5atm) and still get proper a/f mixture by raising the pressure in the meter via opening the regulator up more. sch80 tested to 250+ PSI is generally accepted as safe for remote detoantion which is what i am doing via stun gun. TSI, thanks for the reply. I just wanted to make sure (i know you would know) as alot of other things (ether and paint thinner and similarly cheimcally composed liquids soften and then weaken the PVC) affect PVC and i know Polyester resin and alot of plastics dont get along. I would love to build it from steel or cast iron pipe but the largest i can find locally is 1 3/4". also, i would still have to use a PVC union as i have no idea where you would get a steel union. however my union i have is sch80 and can handle "300PSI" and PVC is grossly underrated (sch40 ratedto 235PSI has been known to reliably handle 250psi pressure spikes) i geuss i could build a mini hybrid but at that rate i may as well just go get a muzzle loading riffle. |

||

|

|

|

|

|

#7 | |

|

Professional Ninja Killer

Join Date: Nov 2002

Location: Penn Hills, Pennsylvania

Posts: 3,561

Thanks: 0

Thanked 10 Times in 10 Posts

|

Re: PVC & Polyester Resin

The biggest problem here is that polyester resin won't stick to PVC. It might lightly bond, but one good tap with the back of your hand and it will slide right off the pipe, so I doubt it would offer much strength.

__________________

Dragging people kicking and screaming into the enlightenment. |

|

|

|

|

|

|

#8 | |

|

Banned

|

Re: PVC & Polyester Resin

do you think sanding and primeing the pipe first will help?

|

|

|

|

|

|

|

#9 | |

|

Forunn Daberator

Join Date: Mar 2004

Location: bumblefuck, Texas

Posts: 10,590

Thanks: 363

Thanked 364 Times in 309 Posts

|

Re: PVC & Polyester Resin

It doesnt have to stick to it in order for it to reinforce it. Also one tap and its not going to slide off, unless you coat it in grease first its not going to come off without a fight, more than likely you'll have to break the pvc out before it will come off. Trust me, if it right off- making fiberglass tubing would be easy.

__________________

|

|

|

|

|

|

|

#10 | |

|

Banned

|

Re: PVC & Polyester Resin

so you think i should use greased PVC as a mold and then just make fiberglass tubing? at that rate it seems may as well leave the PVC in there so can use PVC fittings.

|

|

|

|

|

|

|

#11 | |

|

Banned

|

Re: PVC & Polyester Resin

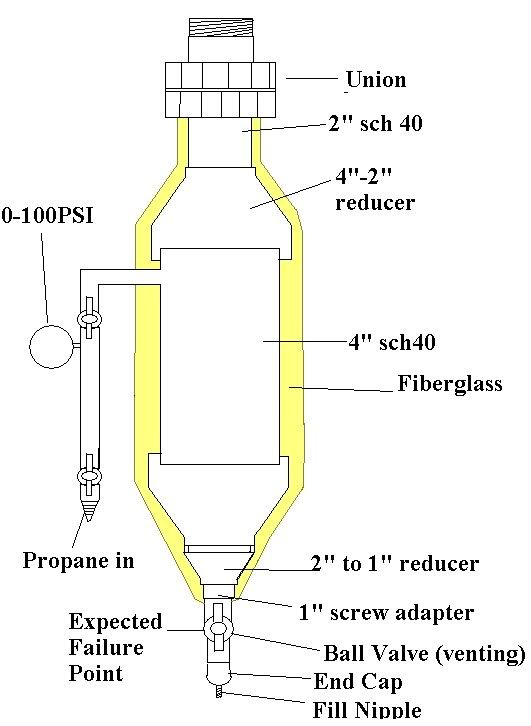

Here is a crude idea of what i am doing.

The expected failure points are the ball valve for venting/filling (to vent i will just spray compressed air through the chamber for so many minutes) and less likely the union. Why these two componets? im doubting the chamber will blow and these two componets would be the safest in the event gun where to blow as the shards would be the largest and heaviest and the pressure least direct so they wouldnt go as fast or as far. it will be remote detonated with a stun gun (as already stated) and loading will go as follows. 1.) Load potato into barle 2.) Unscrew union and insert burst disk (either aluminum foil, duct tape, or walmart bags) and screw union back togather. 3.) close vent valve and 2nd valve on the propane meter. open first valve on porpane meter, charge propane meter to desired presure for the atmospheric pressure the gun is to be fired at for this particular round. 4.) close 1st valve on propane meter and open 2nd allowing propane to enter chamber. 5.) connect air hose to nipple and open vent valve, presurize to desired atmospheric level and level in required for ammount of fule released into the chamber. 6.) close vent valve and remove air hose. close 2nd valve on propane meter and turn on chamber fan (to throughly mix air and fule) remotely. 7.) turn off chamber fan and fire (remotely). then vent and repeat. the fan is started remotely because even though computer fans dont use prush motors a spark could happen and ignite the charge.  |

|

|

|

|

|

|

#12 | |

|

AF Newbie

Join Date: May 2006

Location: Buffalo, New York

Posts: 82

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: PVC & Polyester Resin

If you sand the PVC the 'glass will create a mechanical bond. use 220 or lower. It would be better if you made the thing out of one peice of 'glass-- all at one time. However, if you can"t make fiberglass without voids, you are wasting your time!!!!

|

|

|

|

|

|

|

#13 | |

|

AF Newbie

Join Date: May 2006

Location: Buffalo, New York

Posts: 82

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: PVC & Polyester Resin

Expected failure point---Use a brass ball valve

|

|

|

|

|

|

|

#14 | |

|

Banned

|

Re: PVC & Polyester Resin

though this is a pretty old thread, i still havent gotten around to it. Expected failure point is there for a reason, If something goes wrong id' rather it be the valve in the back than the chamber.

|

|

|

|

|

|

|

POST REPLY TO THIS THREAD |

|

|

|