Two things;

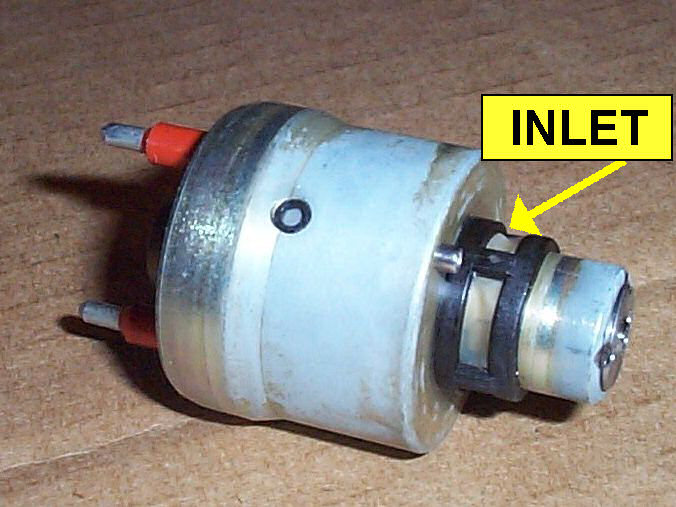

1. That is probably acutally the roll pin used to locate/position the injector in the pod, so pay attention to orientation when assembling. Fuel is actually admitted to the injector via the nylon screen surrounding the lower extension.

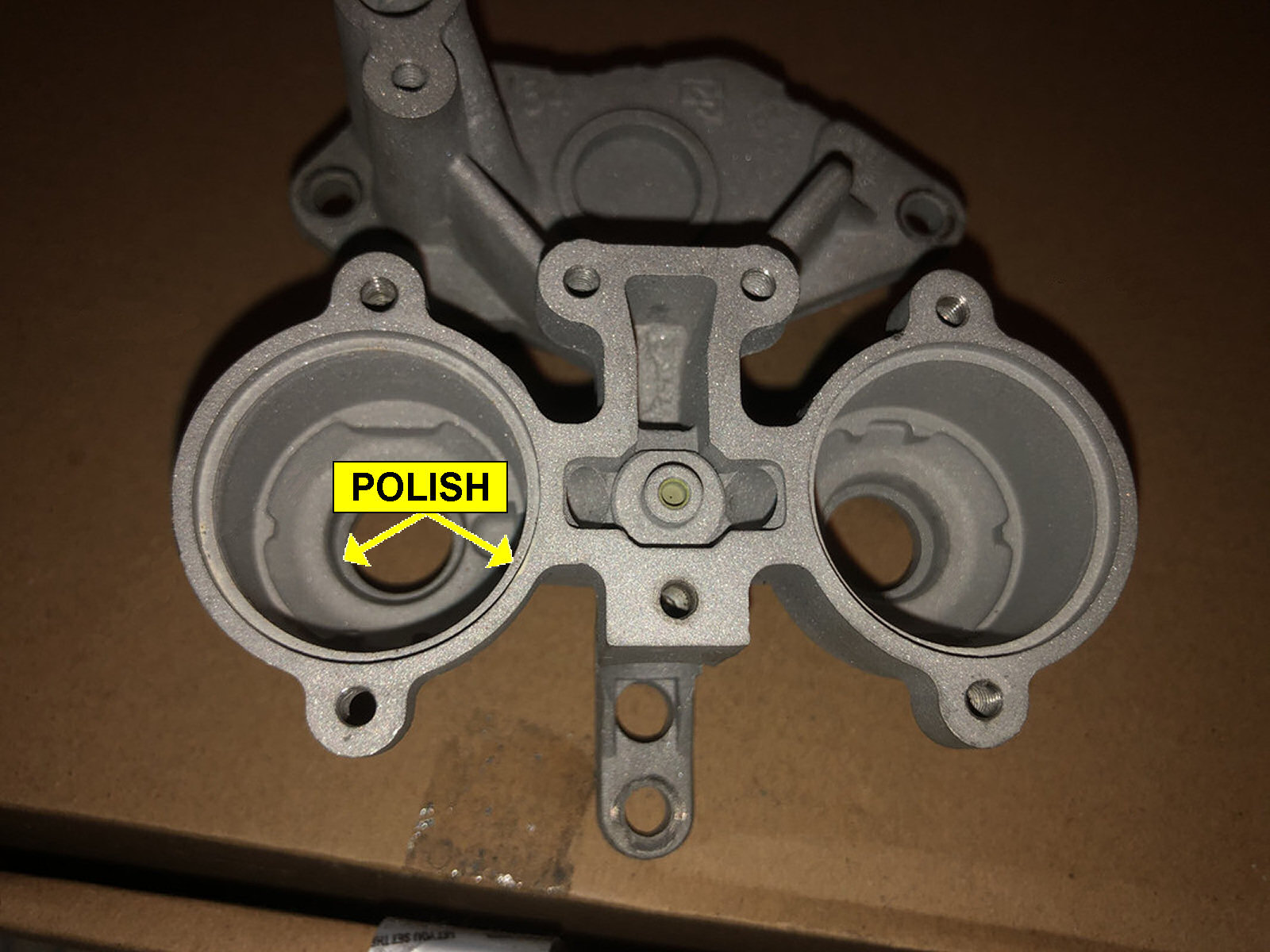

2. It appears the injector pod casting has been bead blasted. That's going to make it pretty difficult for the O-rings to seal the injectors to the casting, and may result in fuel leakage. There is a specification for surface finish for a typical static O-ring, and I would bet that a blasted surface is nowhere near the spec of 16 ra (microinches) RMS, or 0.4 microns. In fact a smoothly machined surface produced by a larger radius tool tip often only barely achieves that. A 150 grit glass blasted surface is frequently aound 50 ra.

https://www.parker.com/literature/Section IV.pdf

Do you have any surface finish gauges? if not, this is one of the cheapest you might find:

https://www.amazon.com/SRT-6200-Digi...F4VAPGWRG4JM72

Polishing with a 240 grit abrasive can produce (barely) a 16 ra. Polishing with 320 grit abrasive can produce 8-10 ra, which would be acceptable. You may have some work to do, but it's not going to be easy down in the lower O-ring seat.