|

|

| Search | Car Forums | Gallery | Articles | Helper | Air Dried Beef Dog Food | IgorSushko.com | Corporate |

|

#31

|

|||

|

|||

press release: The impetus for the Kappa architecture's world-class platform was the Pontiac Solstice. A strong response to the 2002 Solstice concept car helped green-light the vehicle for production even though a compact rear-wheel-drive platform for it did not exist. A core team of engineers was assigned to develop one - and quickly. This efficient team collaborated globally to develop a flexible platform that would enable future production work for a distinct set of GM brands. "We knew from the start that we would do it right or not do it at all; the support for that decision came from the very top," said Lori Queen, vehicle line executive for GM's small cars. "It has been an experience whereby the size and strength of GM was mobilized on a global scale to get the job done immediately." To maintain the Solstice concept's aggressive stance, the chassis was developed to support the vehicle's short overhangs, long wheelbase and wide stance. This "wheels at the corners" design enhances handling and the overall feeling of stability. It also allows for a more comfortable interior, with increased legroom and hip room. To ensure the lithe proportions of the Solstice were complemented with a firm foundation, engineers developed a lower-dominant tube structure for the chassis. Hydroformed frame rails, which run the length of the vehicle, are the basis of the chassis, while additional stampings form a rigid structure onto which the bodywork is attached. The hydroforming process uses pressurized fluid to form each frame rail from a single piece of steel, rather than several pieces of steel welded together. This creates a stronger frame rail and requires less time to form it. Additional components and stampings are added to the frame rail during vehicle assembly. A tunnel at the center of the chassis, which houses the transmission and driveshaft, is enclosed at the bottom to enhance stiffness. This built-in strength reduces chassis flex and cowl shake in a vehicle designed from the outset as a convertible. "Convertibles typically are less stiff than vehicles with a fixed roof, so we set out to create the stiffest possible platform for a vehicle this size," said Queen. The Kappa architecture's rigid structure also permits more precision when it comes to tuning the suspension. The Solstice features independent, SLA-type suspensions in the front and rear, along with coil-over springs wrapped around Bilstein monotube shock absorbers. The short-long arm suspension designs feature forged aluminum upper and lower control arms that are both strong and lightweight. The rear suspension also features a toe control link and the rear differential housing has an optimized three-point mounting design. The Kappa's suspension design and geometry are not shared with any other GM vehicle architecture. The Solstice also features four-wheel disc brakes, including 11.7-inch ventilated front rotors and 10.6-inch rear rotors, which combine with optional ABS with Dynamic Rear Proportioning to provide superior stopping stability. Eighteen-inch wheels are standard. Dynamics Perfected In addition to the robust chassis architecture and suspension components, Kappa engineers sweated dynamic details to produce a world-class platform, including: - Near 50/50 weight distribution for a balanced handling feel - Hydraulic engine mounts to provide a smoother engine feel - Optimized acoustic barrier and sound absorption package to provide world-class levels of interior quietness - Exterior components, such as mirrors, wind-tunnel tested to minimize wind noise - Tires selected for handling performance and low noise. The Kappa chassis also was designed for the all-aluminum Ecotec four-cylinder engine. In the Solstice, the 2.4-liter version of the sophisticated DOHC powerplant features twin balance shafts to reduce engine-sourced noise and vibration. Technologies including intake- and exhaust-cam phasing and electronic throttle control are employed to maximize volumetric efficiency, boosting the smoothness and performance of the engine throughout the rpm range. Clear Mission Development time and cost were reduced by leveraging existing GM components where possible. The Solstice's rear differential, for example, is borrowed from the Cadillac CTS. Other proven component selections also aided Kappa architecture's development time. "It makes sense to leverage proven parts that fit the application," said Queen. "The parts are adapted to the Kappa architecture and do not compromise the vehicle's design or function." Knowledge that the Solstice would be offered with a version of the Ecotec four-cylinder engine allowed the chassis team to design for the specific powertrain from the project's start. Because the Ecotec engine had not previously been used in a longitudinal layout, several accessory drive components required redesign to fit the new chassis. "Knowing these challenges at the beginning helped us design it right the first time," said Queen. "We had a very clear mission on how to proceed with the architecture's design." Although the primary focus of the Kappa architecture was the development of the Solstice, its platform is adaptable - as demonstrated with the Chevrolet Nomad sport wagon and Saturn Curve 2+2 coupe concept vehicles. The Nomad rides on a longer wheelbase than the Solstice for added rear passenger room, while the expressive Saturn offers a sophisticated, performance-oriented driving experience with a fixed roof. "The Kappa architecture is a great platform for sporty, driver-oriented applications around the globe," said Queen. "Two years ago it didn't exist, but as the other concepts show, the additional possibilities are tantalizing." Last edited by Jaguar D-Type; 12-03-2005 at 08:33 PM. |

|

#32

|

|||

|

|||

|

"Solstices have been running down the final assembly line for months. And when the cars have been built, they've been sent backward down the line, disassembled, and rebuilt to fine-tune the process."

- Motor Trend July 2005 |

|

#33

|

|||

|

|||

Last edited by Jaguar D-Type; 12-03-2005 at 08:32 PM. |

|

#34

|

|||

|

|||

|

Rear suspension:

Front suspension:

Last edited by Jaguar D-Type; 12-03-2005 at 08:47 PM. |

|

#35

|

|||

|

|||

|

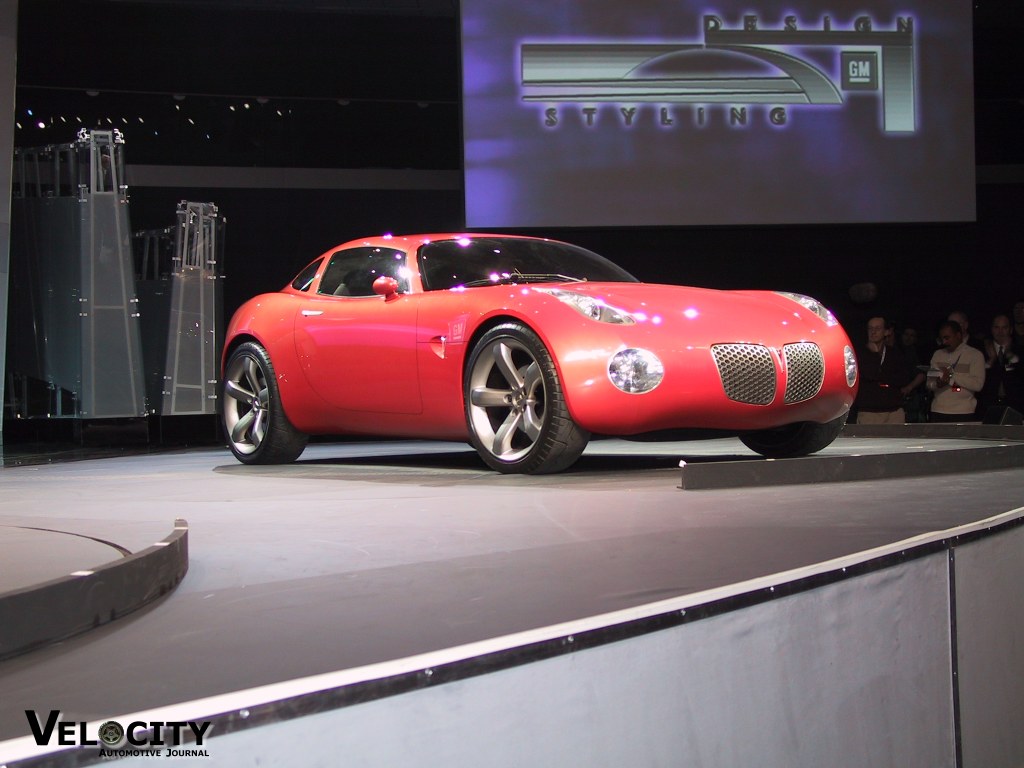

2002 Pontiac Solstice Coupe concept

Last edited by Jaguar D-Type; 07-22-2005 at 07:05 PM. |

|

#36

|

|||

|

|||

|

Several hundred Solstices will be delivered this month (August).

|

|

#37

|

|||

|

|||

|

The Solstice delivery party was on August 5th.

Last edited by Jaguar D-Type; 12-03-2005 at 08:45 PM. |

|

#38

|

|||

|

|||

|

Re: all-new 2006 Pontiac Solstice

well my mom just got put on a list and actually test drove one and she said she loves it and wants it but im wondering if they are going to shoot this one out first and come out with a more powerful one in a few months. anyone have any insight as to if they have a different model going up

__________________

Team Addiktion 155 down the 47 Last edited by dsmkid95; 08-24-2005 at 08:01 PM. |

|

#39

|

|||

|

|||

|

Well, the new Solstice comes with a 2.4 liter DOHC 177 hp I-4 and it might get a 200+ hp 2.0 liter supercharged or turbocharged I-4 for the 2007 model year.

Last edited by Jaguar D-Type; 12-03-2005 at 08:46 PM. |

|

#40

|

|||

|

|||

|

Re: all-new 2006 Pontiac Solstice

hmm...decisions decisions.

__________________

Team Addiktion 155 down the 47 |

|

#41

|

|||

|

|||

|

March 2004

ai-online.com Credit GM’s car czar Bob Lutz for conjuring up the Pontiac Solstice as his first act after walking into the executive suite a few days before the World Trade Center came tumbling down. What began as a last minute concept for the 2002 North American International Auto Show breathed life as if by divine intervention. Rather than build the push toy the boss had conceived, Engineering Executive Mark Reuss and project manager Mike Lyons conspired to build a driveable prototype … in about 100 days. After enthusiast magazines raved and show goers mailed deposit checks, GM knew it faced a daunting challenge: converting Lutz’s brilliant concept into a hot Pontiac with profit potential. Enter Lori Queen, GM’s vehicle line executive for small cars and Doug Parks, the Solstice’s chief engineer. “We began studying how to build Solstice soon after its show debut,” Parks recalls. “One early idea became known as ‘Delta with a tunnel.’ [GM’s Delta platform underpins the current Saturn Ion and the coming Chevrolet Cobalt.] “The hope was to save investment costs by building Solstice on the same line that manufactures volume models. Unfortunately, by the time you add a tunnel and factor in the changes necessary to convert a transverse front-drive car into a longitudinal rear-driver, costs rise. It became clear that a modified Delta wouldn’t work so we began investigating a new architecture. The challenge was finding a low investment approach that would enable a 20,000 units per year program to make money.” Complicating matters were natural forces within GM to make Solstice longer, shorter, wider, and taller in hopes of stretching the platform’s potential. Variations on the theme were examined and presented to upper management in pursuit of a green light for production. But the reactions of Lutz and GM President Gary Cowger surprised the investigation team. Parks explains, “They said ‘Wait a minute guys. All these variations, which are close but not the same, don’t look any better than the show car. And from an engineering standpoint, they aren’t any better. Furthermore, there’s no problem packaging the necessary components.’ Collectively we agreed that the original concept was a fantastic accomplishment that had earned GM heaps of praise and there was no good reason to mess with that success. So we decided to simply nail the show car.” Queen explains that Solstice couldn’t have progressed in a timely manner were it not for the engineering integration that GM has achieved during the last five years, “Our most notable strength is our size." But GM’s dilemma has always been leveraging that size to our advantage. “Thanks to recent reorganizations, GM now has a global linkage through system management teams (SMTs) that are knowledgeable about components available all over the world. Since we have a vast reservoir of parts bins to draw from, we began creating the new Kappa architecture by asking the SMTs to identify GM components most suitable for this small rear-drive application. Immediately, we found seats from the Opel Corsa and a suitable differential from the Cadillac CTS. If it’s already tooled, we know all the pros and cons of a particular part and its history.” Parks adds, “Not having to engineer an engine, transmission, instrument cluster, or the car’s electronics saves a lot of time. The brakes and suspension knuckles are also reused.” According to Queen, the goal was to chop the normal vehicle development process in half. “We used math everywhere we possibly could and built only a few physical properties. When possible, we went straight to production tools and built vehicles in the assembly plant. The whole development process was re-written and the critical path was changed. To go fast we took some risks. But we found our math capabilities are astounding and they did an excellent job of predicting how the hardware would perform.” Parks adds, “The cars have been designed, released, and we’re building production tools without a crash test. Instead we’ve gone through hundreds of computer simulations. If we find it necessary to tune the crash pulse, we have plenty of time to accomplish that by altering production tools.” “Changing the critical path and relying heavily on math data allowed us to trim the normal 42-month process to 28 months,” beams Queen. A speedy development process was just one means of keeping the price below $20,000 for a Pontiac steeped in sex appeal and sporty performance. Parks explains, “While Solstice was still in the advanced investigation phase, we examined several attractive technologies such as one magnesium casting to serve as the entire front of dash, a composite center tunnel framed by four tubes, and a hydroformed windshield header." “While the potential for lowering investment was good, some of these approaches posed a high risk. What was lacking was a proven strategy that could tie the components together with the desired dimensional accuracy. That risk inhibited our ability to go fast with this program." “Even though the design evolved into a more conventional approach, we kept a structure that’s primarily MIG-welded hydroformed tubes. And some of Kappa’s makeup still falls under the heading of high risk.” The key structural elements are a pair of hydroformed tubes that run bumper to bumper. Two additional hydroformed tubes define the bottom corners of the driveline tunnel. The four tubes attach to transversely oriented stamped panels via MIG welds. The floor and tunnel are also ordinary stampings spot welded together and then bonded with adhesives to the structural framework. Using a technique developed for the Corvette, the front-of-dash and windshield frame are built up as a subassembly and then mated to the rest of the unibody with adhesives and a few welds. Bumpers and the instrument panel support beam are roll formed. Parks continues, “The more traditional approach cut risk and saved engineering time though it did increase the investments necessary for more stamping dies. That said, the hydroformed tubes we incorporated are far less expensive than a conventional body’s construction because they integrate several parts, thereby eliminating numerous welding fixtures and assembly tools.” That in turn changes how Solstice will be manufactured. Notes Queen, “Solstice’s unique construction and low volume results in a body shop that looks nothing like those that use GM’s standard bill of process. Instead of having robogates clamp everything together in a fixture prior to welding, we’ll have smaller fixtures that set the dimensional accuracy piece-by-piece. Some of the MIG welding is automatic but most of it will be done by hand. “The amount of work necessary to build this car in just a few stations is significantly less than what’s necessary for a conventional body. There aren’t that many welds because adhesives and fasteners are also used to join parts. While hydroformed tubes are commonplace in body-on-frame applications such as full-size trucks and the Corvette, Kappa brings a new twist to body making called sheet hydroforming. While this technology is rare in the car business, it’s been in wide industrial use for decades. Chances are your notebook computer’s case or the stainless steel sink in your kitchen was made by this method. According to Al Houchens, GM’s director of advanced manufacturing technology productionizing, sheet hydroforming delivers several benefits: - A 10-50-percent tooling-cost savings. - The ability to draw deeper-section panels with more complex shapes than is practical with conventional processes. - Superior finish quality since there is no skidding friction or metal-to-metal contact on the visible surface. - Added stiffness achieved by hydroforming’s more equitable spread of strain over the panel’s entire surface, improving dent and oil canning resistance. The one notable negative is a cycle time three to 10 times longer than conventional matched-die stamping. That’s a show stopper with high volume models such as the Chevrolet Cobalt but not a concern when the sales target is 20,000 or so sports cars per year. The entire skin of the Solstice and mating inner panels — about ten parts in all — will be made by sheet hydroforming. Elated with this breakthrough approach, Queen exclaims, “We considered SMC and other composites but plastics drove investment and piece costs too high for a low-volume, low-cost car. And the beauty of sheet hydroforming is its ability to produce a hood with shapes, forms, and radii that couldn’t be achieved with conventional stamping methods." “What’s more, the Kappa architecture doesn’t preclude other technologies. There’s no reason we couldn’t use aluminum, SMC, or conventional pressed steel for another car sharing this architecture.” Parks adds, “Substituting longer hydroformed structural rails gives us a longer wheelbase. The chassis is a suspension engineer’s dream with forged-aluminum control arms and coil-over dampers so there’s ample capacity for other family members." “The beauty of the Ecotec engine is that, with turbocharging or supercharging, it’s capable of delivering 250 hp which would take us from seven seconds for the base car’s zero-to-sixty performance down to the five-second range. In other words, the 4-cylinder offers so much flexibility we see no need for a V-6.” The 2.4 liter Ecotec 4-cylinder engine was switched from front to rear drive without any engine block modifications needed. The stamped-steel center tunnel is reinforced with hydroformed tubes. The front-of-dash and windshield frame are built up as a subassembly and mated to the unibody with adhesives and a few welds, a technique developed for the Corvette. front/rear suspension: forged aluminum unequal-length control arms, monotube dampers, coil springs Last edited by Jaguar D-Type; 08-26-2005 at 01:00 AM. |

|

#42

|

|||

|

|||

|

Re: all-new 2006 Pontiac Solstice

pontiac taking a step in the right direction...finally

|

|

#43

|

|||

|

|||

|

Mallett is going to make 100 modified Solstices with a 400 hp LS2.

Check the link http://www.mallettcars.com/solstice-conversion.htm

|

|

#44

|

||||

|

||||

|

beautiful vehicle.

agressive and trendy. Pontiac is catching up to where it was in the past. still a shame that an "eco"-tec can't get better than 30mpg. open air cockpit and 50/50 weight distribution definite plus. |

|

#45

|

|||

|

|||

|

The Solstice shown is a pre-production car.

I think it lacks the premium package, but I could be wrong.      Columbia River Gorge

Last edited by Jaguar D-Type; 12-24-2005 at 11:59 PM. |

|

|

POST REPLY TO THIS THREAD |

|

|

|