|

| Search | Car Forums | Gallery | Articles | Helper | Air Dried Beef Dog Food | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|||||||

| WIP - Motorsports Post topics for any "Work In Process" motorsports vehicles in this sub-forum. |

|

Show Printable Version | Show Printable Version |  Email this Page | Email this Page |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

|

#376 | |

|

AF Enthusiast

Thread starter

Join Date: Nov 2008

Location: Norwich

Posts: 671

Thanks: 23

Thanked 116 Times in 91 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

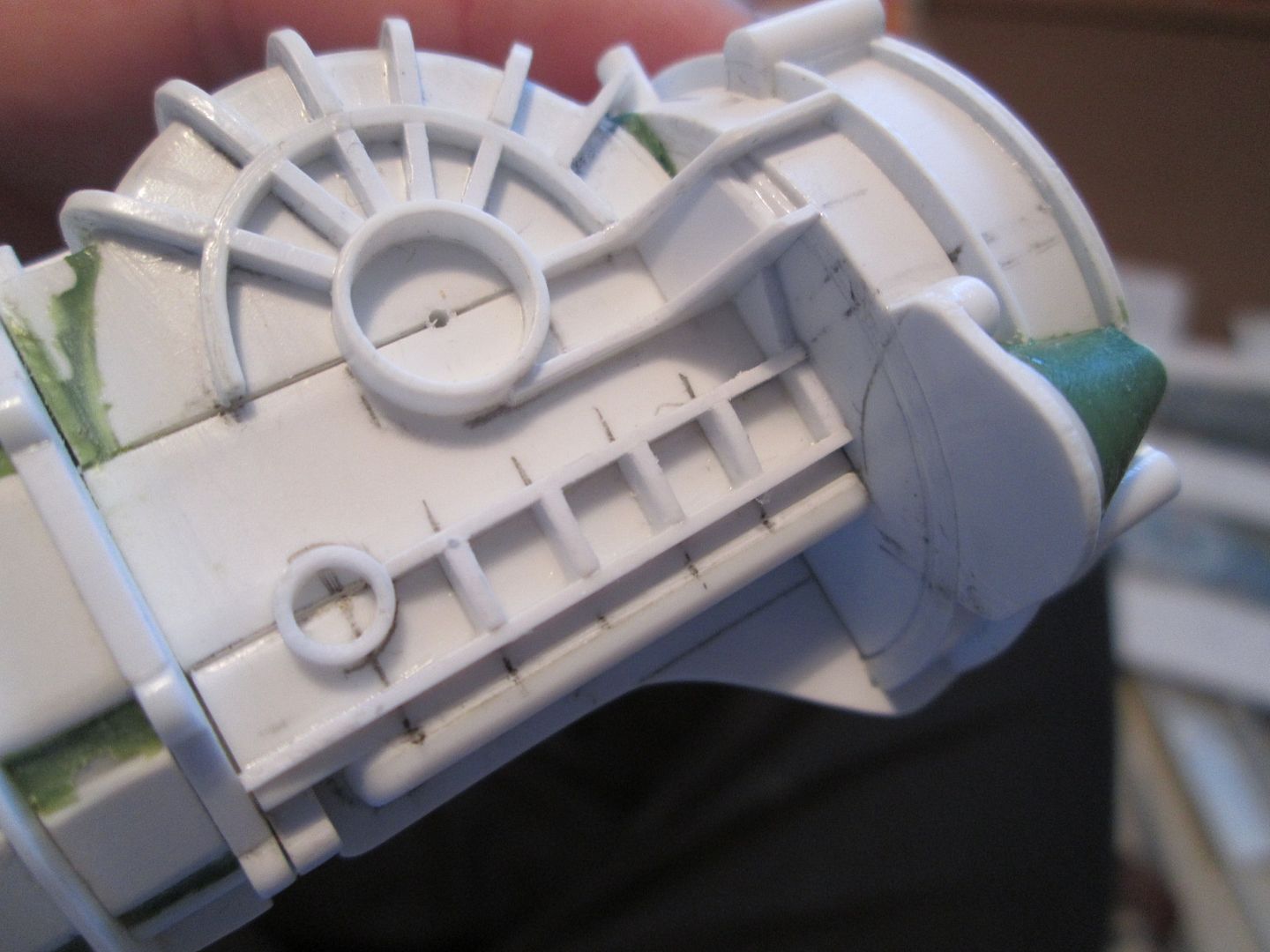

So, before continuing the end-cover detailing and the webbing on the gear-cluster section, I wanted to get the maincase finished. First step was to sort out the bulge in the flywheel housing where the starter motor would attach:

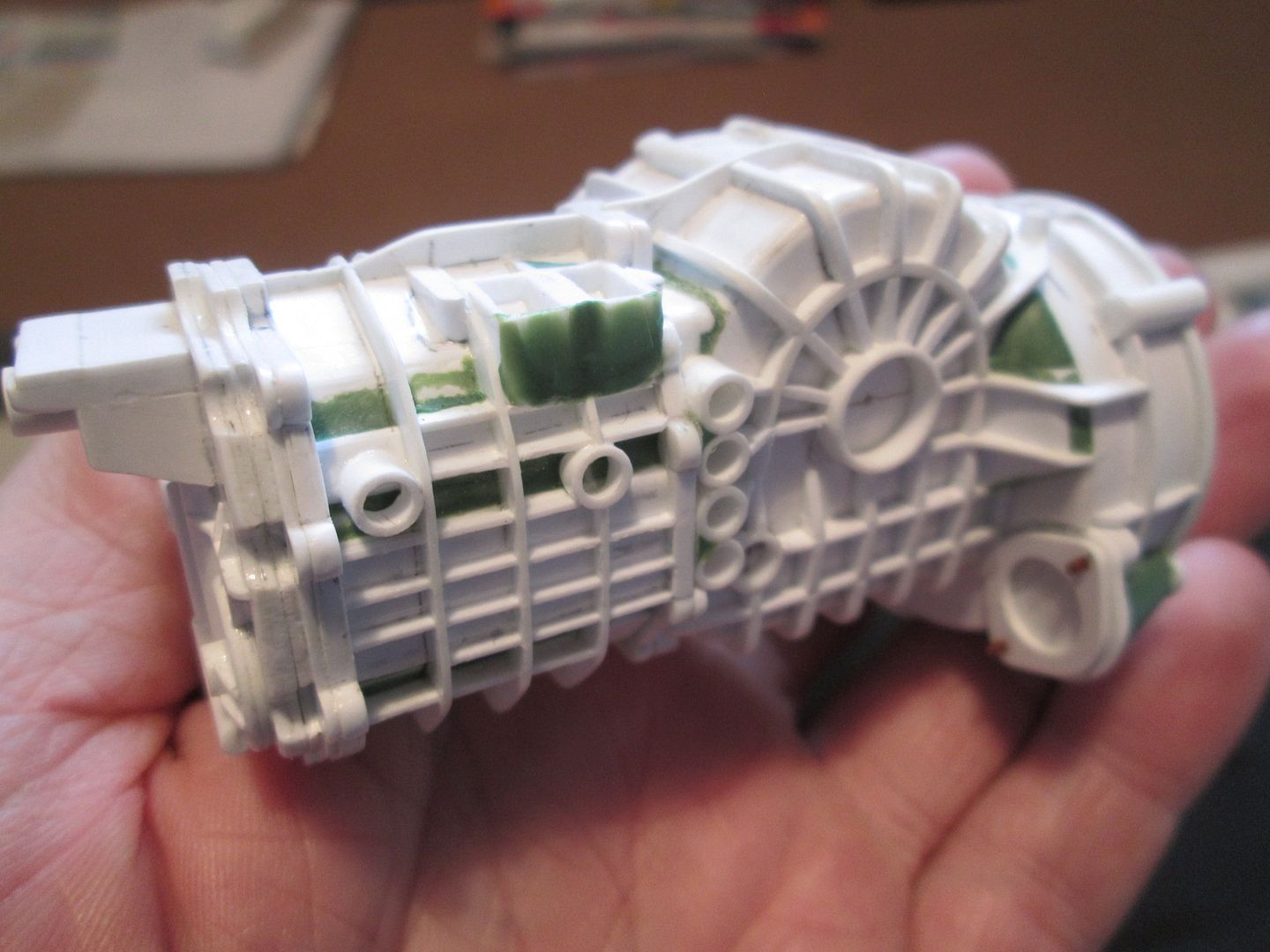

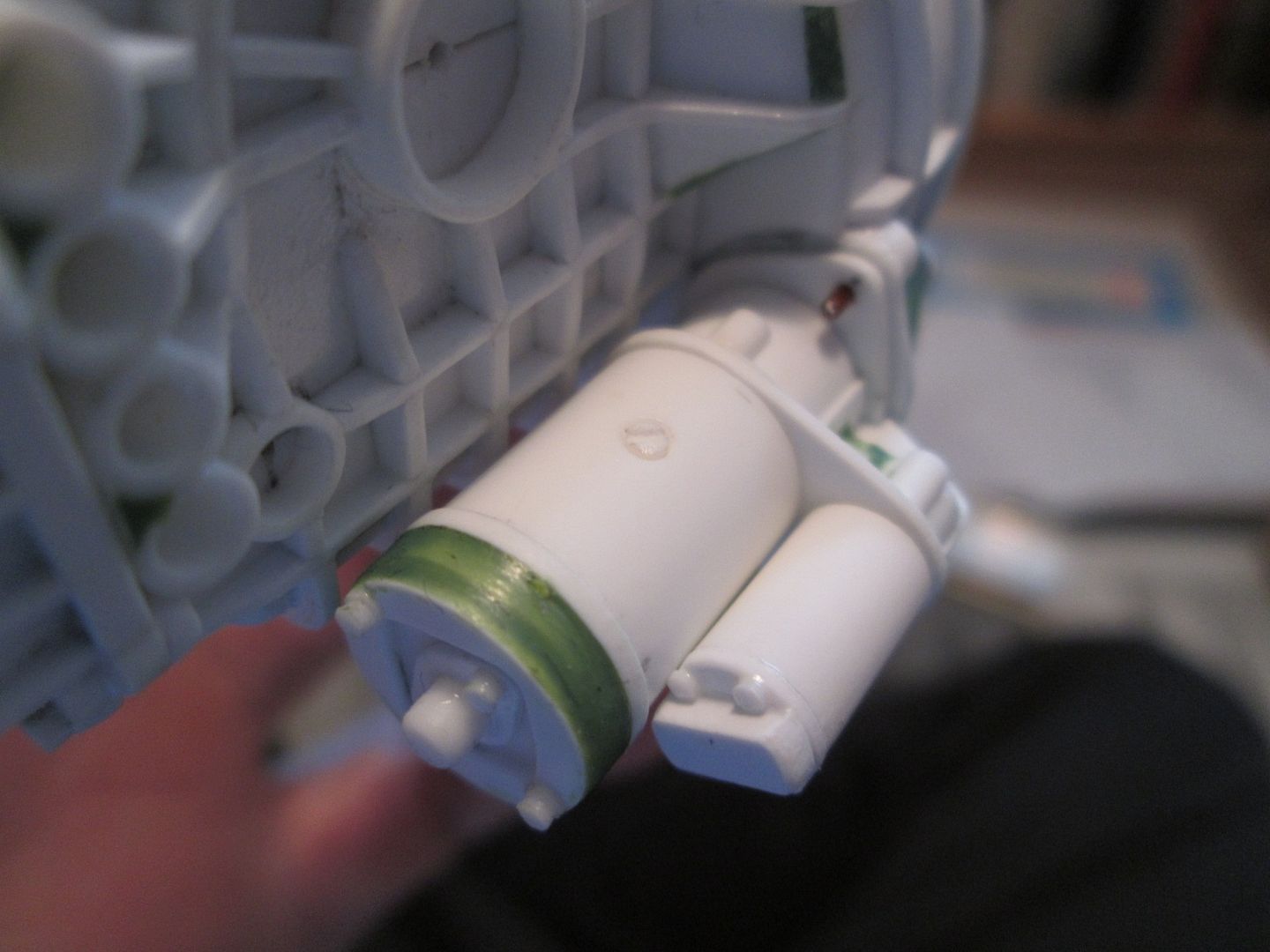

The starter itself is in the early stages here - this is enough to work out whether it fits or not. The bulge was reinforced with a few small bits of styrene before adding the greenstuff:  Then it was a case of adding the webbing - a mixture of 0.75mm and 1mm strip:  In this final photo you can see where I've added some more greenstuff (which needs to be smoothed-out once solid), plus a set of bosses which will eventually have hex-nut detailing too. The starter motor mounting plate was drilled and pinned in place - not really necessary for structural reasons, but it makes it easier to work on if it stays in place!  There's still a bit more to do on this section, but I'm really pleased with my progress this weekend - I had a nearly 12-hour day on this yesterday (with the Nurburgring 24Hr race playing in the background for company). I'd like to think I can get the gearbox finished within the next couple of weeks or so (don't hold me to that!)...there's just one or two details that I want to investigate further which might cause a delay. I should have a week's holiday coming up in early August, so that would be a good opportunity to do some more fibreglassing, or to make a start on the next stage of the project... Have a good week, SB |

|

|

|

|

|

|

#377 | |

|

AF Newbie

Join Date: Jul 2010

Location: Antwerp

Posts: 24

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Great progress on that gearbox SB. The amount of detail you're putting in... incredible.

It looks like the real thing and with coulour on it, you could 've fooled me, that it was. Keep up the great work you're doing. Mark |

|

|

|

|

|

|

#378 | |

|

AF Enthusiast

Thread starter

Join Date: Nov 2008

Location: Norwich

Posts: 671

Thanks: 23

Thanked 116 Times in 91 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Evening all,

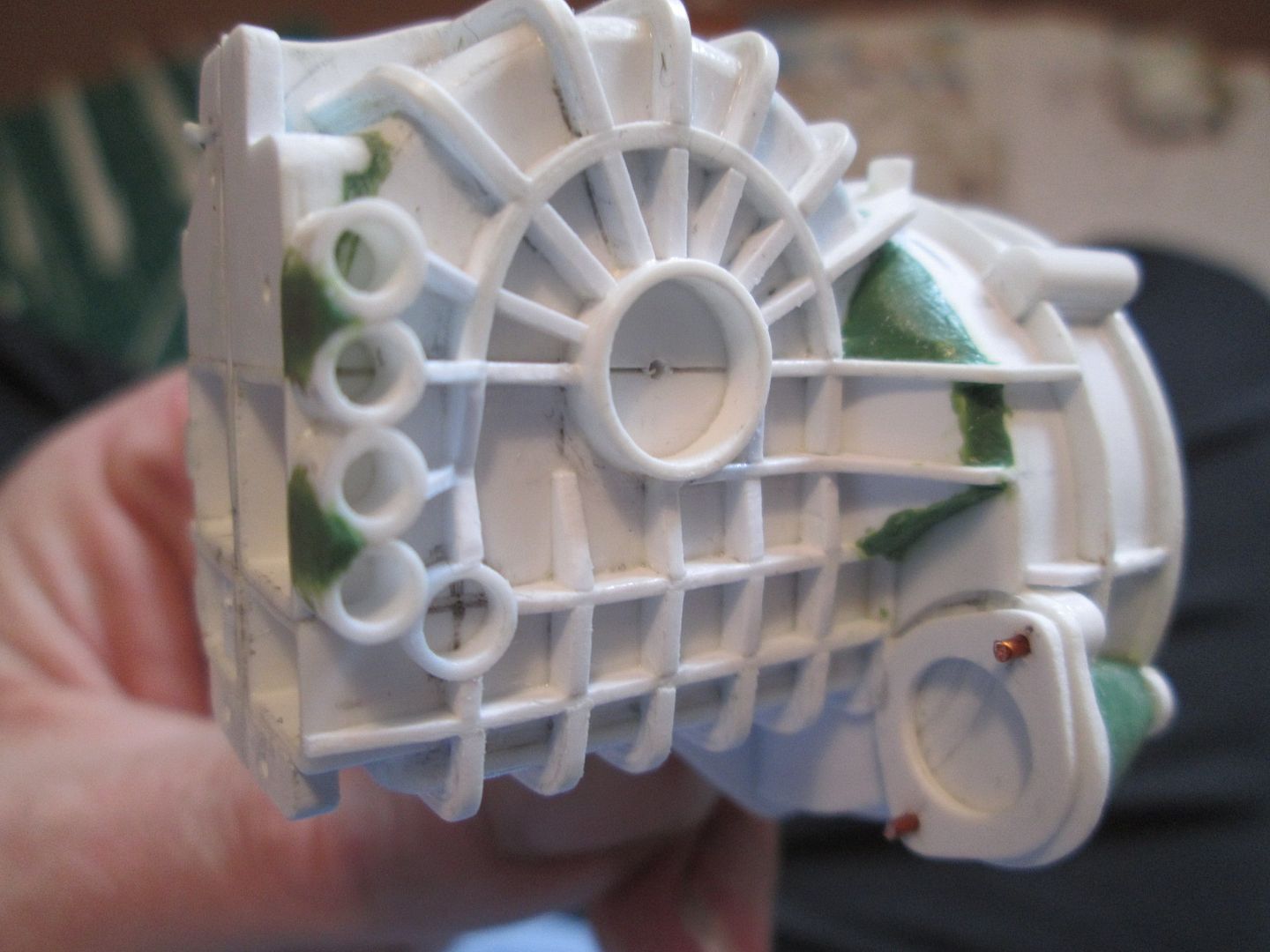

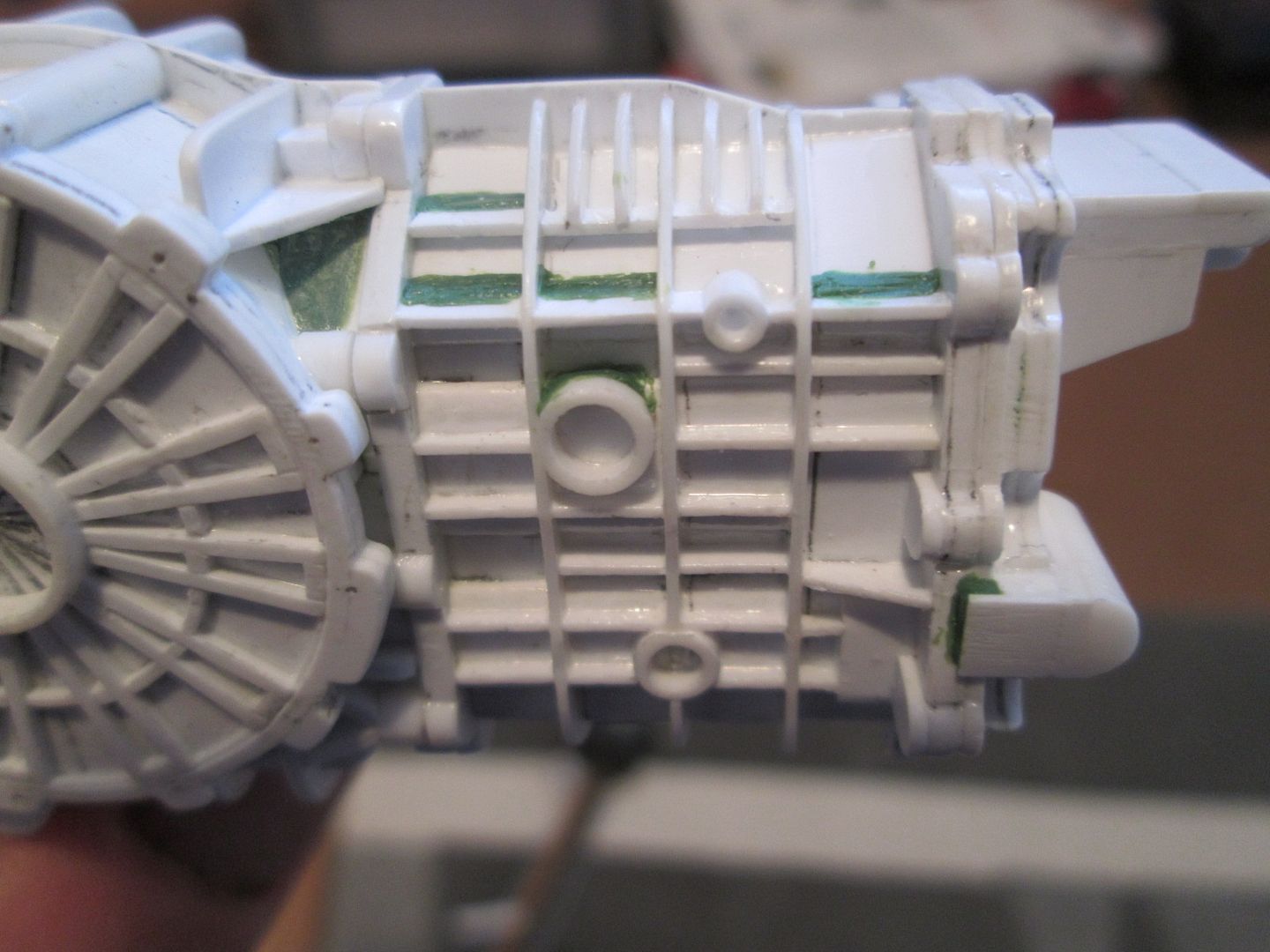

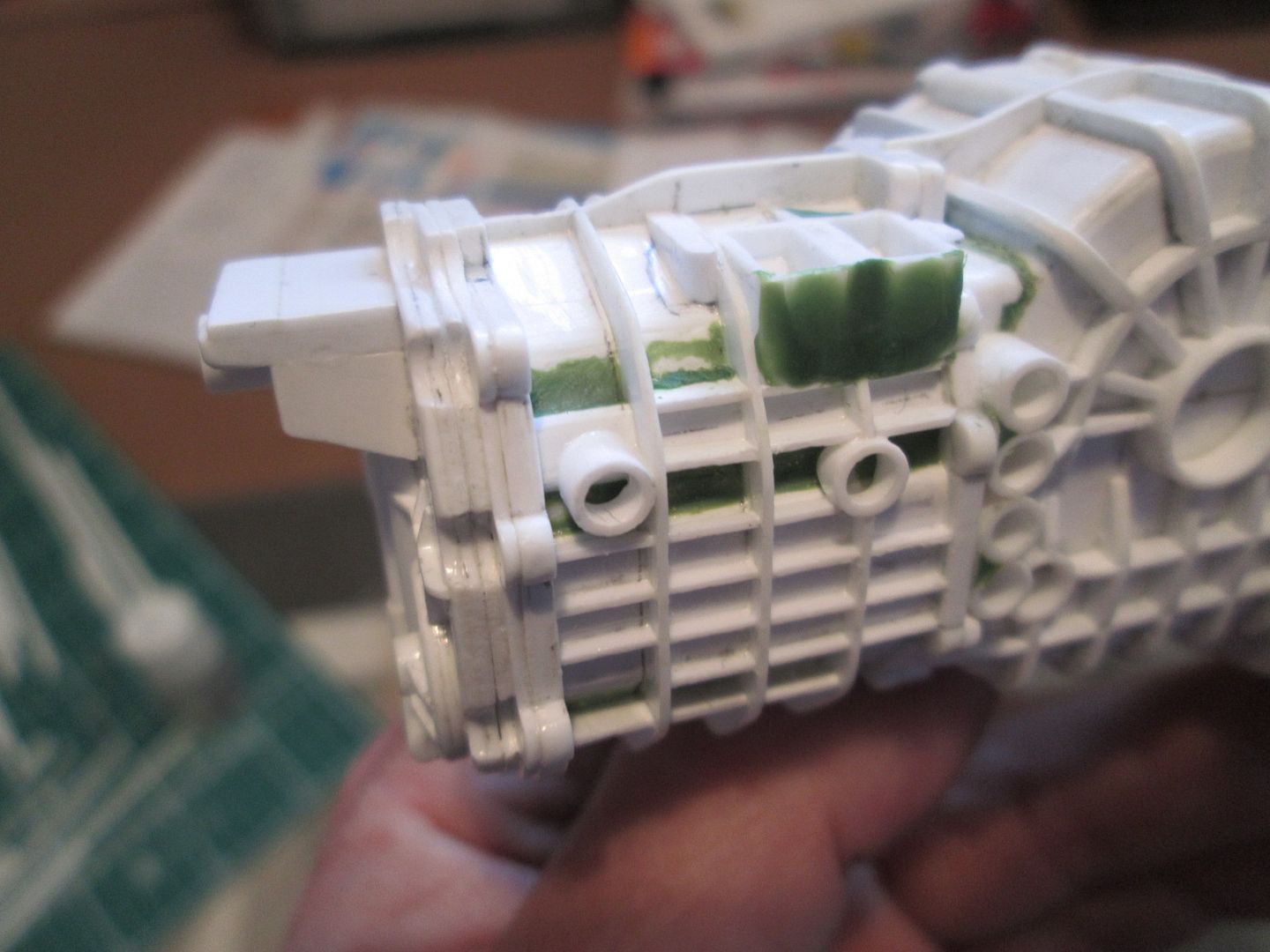

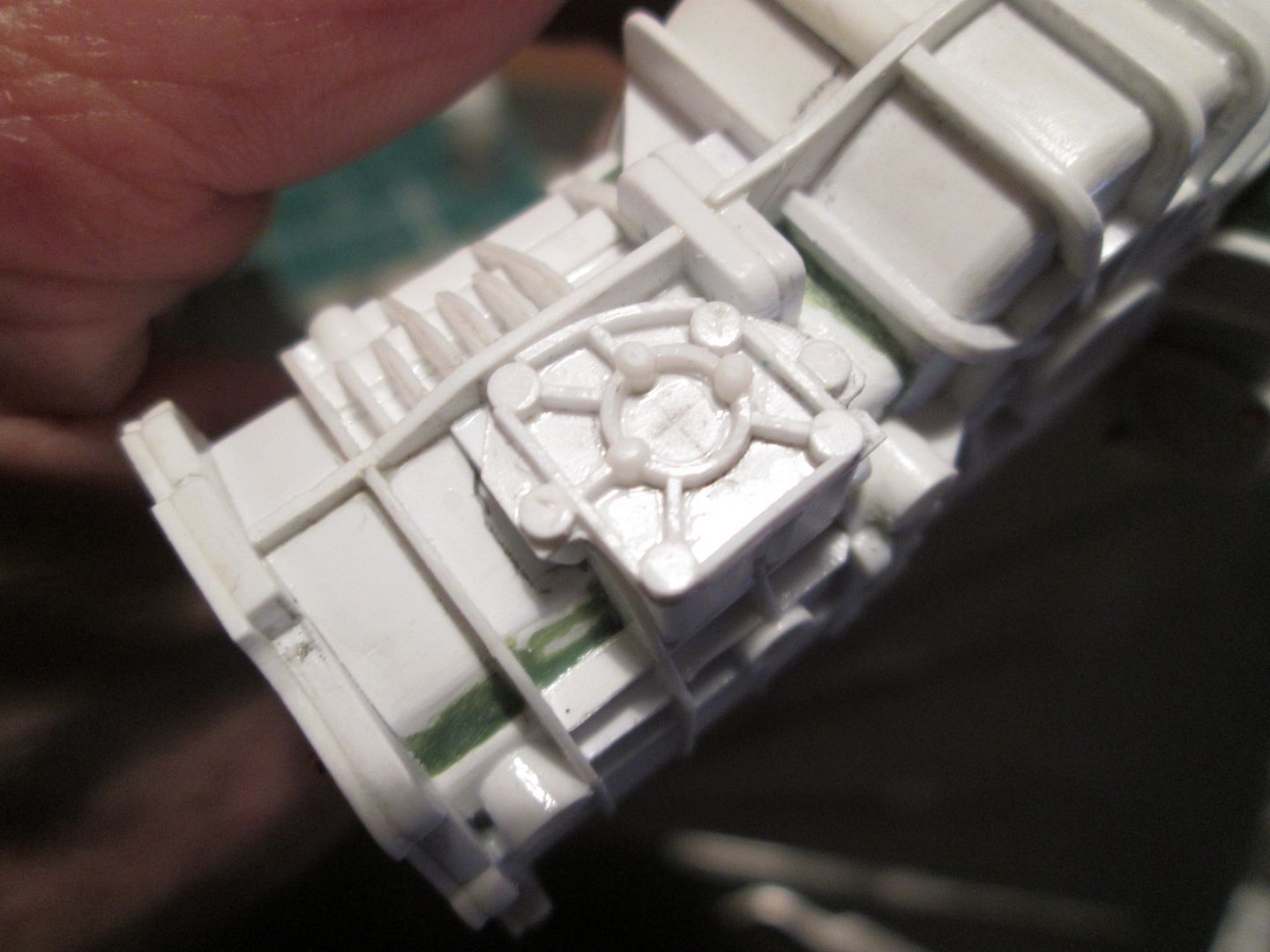

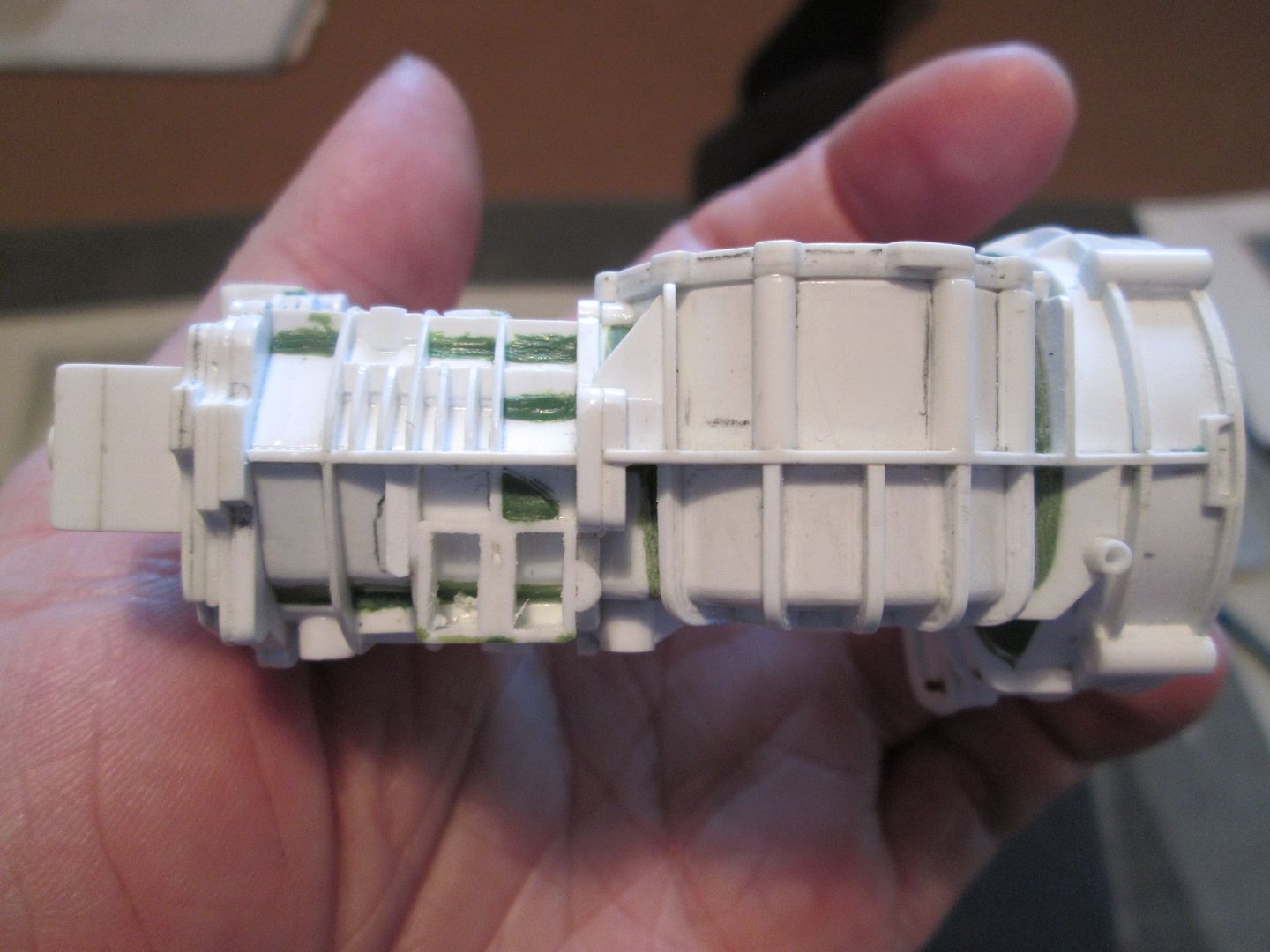

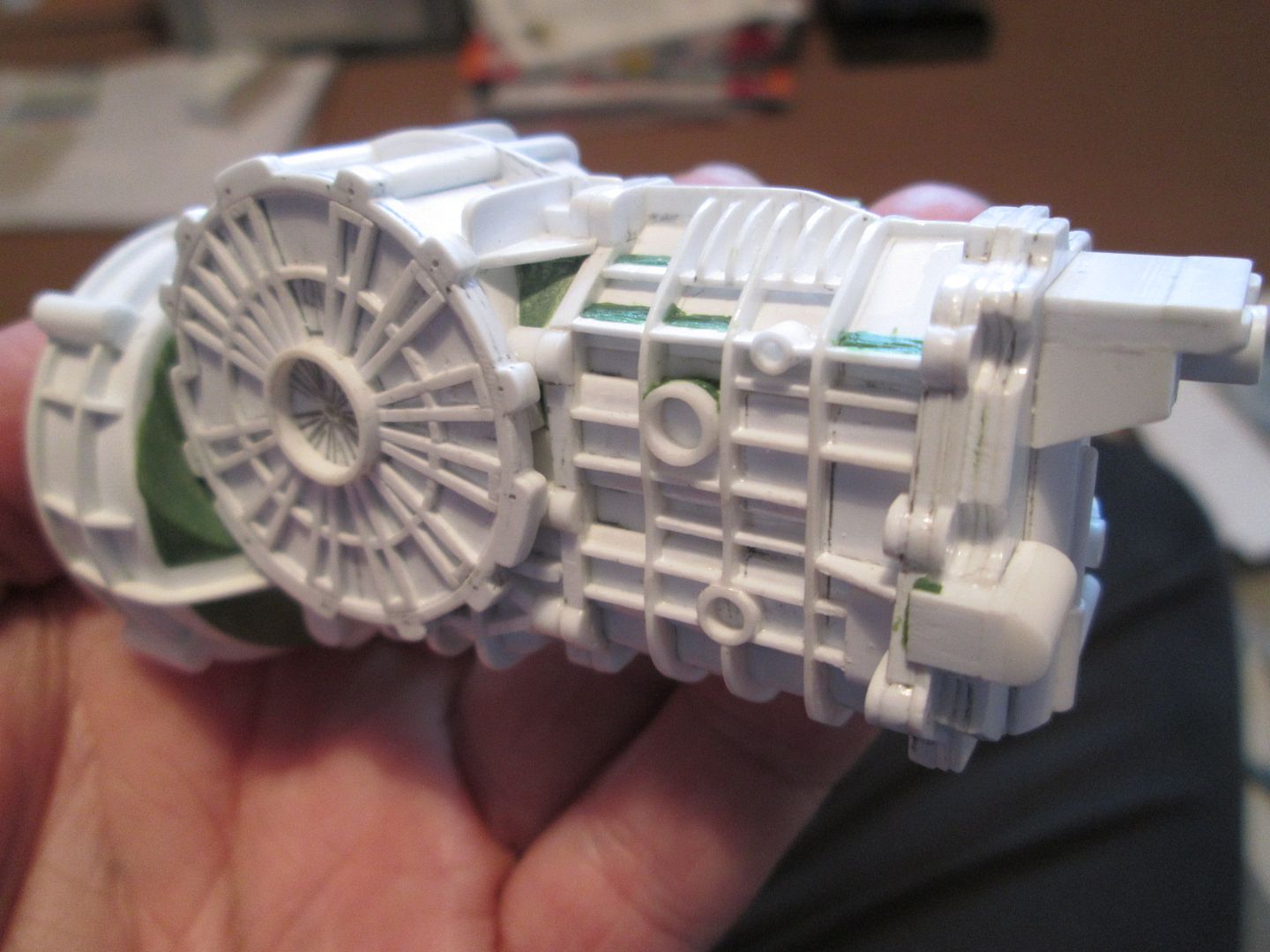

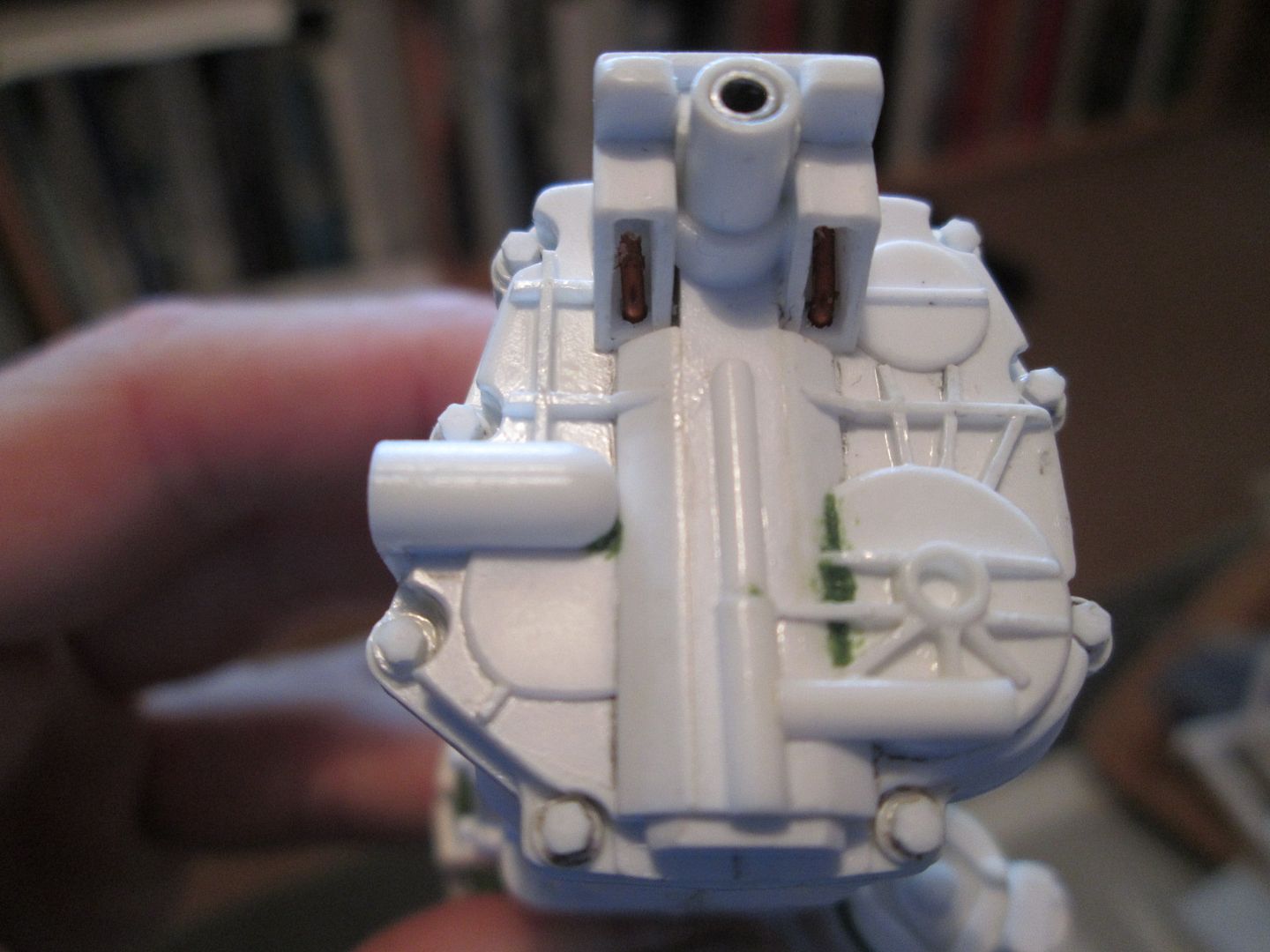

Not a lot to talk about tonight, but it's been a productive week all the same. All my attention has been on adding the outer detailing to the gear-cluster section of the 'box - which has meant gluing the final sections together, and sorting out the joint with the end cover. So, here's a close-up of the right-hand side:  ...and the left:  The fins are all 0.5mm thick, mostly 1mm wide, with some at 1.5 or 2mm depending on the position. The bosses will have various plugs and oil fittings attached later on. The greenstuff was only added late this afternoon, so will need to be filed and fettled tomorrow night. On top I've added the small box which has this cover-plate fitted to it:  The larger bosses at the corners are all 2mm diameter punched from 1mm sheet; the three smaller domed bosses in the middle are 1.5mm rod with a bit of filing. The webbing detail is all 0.5 x 1mm strip, as before. So...it's approaching the final stages now. Hex-nut detailing needs to be added all over, a little tidying and greenstuff here and there, finish the end cover, and that's almost it:    I thought I'd maxed-out on gearbox detailing when I made the 908's, but now I'm not so sure! It'll be a while before it gets painted, but that's when it will really come to life. SB |

|

|

|

|

|

|

#379 | |

|

AF Enthusiast

Join Date: Dec 2009

Location: Hamme

Posts: 535

Thanks: 77

Thanked 21 Times in 17 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Amazing as always SB. What putty are you using? Thanks.

Best regards, Lesley |

|

|

|

|

|

|

#380 | |

|

AF Enthusiast

Join Date: May 2009

Location: Tucson, Arizona

Posts: 1,469

Thanks: 12

Thanked 126 Times in 120 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

unbelievable detail on the gusseting of the casing SB

how do you keep all the ribbing strips so straight and square? John |

|

|

|

|

|

|

#381 | |

|

AF Newbie

Join Date: Jul 2010

Location: Antwerp

Posts: 24

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Lesley, as far as I know, SB uses green stuff as putty.

He's got some amazing results with it, no ? Mark |

|

|

|

|

|

|

#382 | |

|

AF Enthusiast

Join Date: Sep 2011

Location: Redwood City, California

Posts: 651

Thanks: 0

Thanked 39 Times in 39 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Looks great as usual! I don't know how you can resist the temptation to paint each piece as you complete them just to see how they look!

ianc |

|

|

|

|

|

|

#383 | |

|

AF Enthusiast

Join Date: Mar 2009

Location: Zuhause

Posts: 787

Thanks: 176

Thanked 71 Times in 69 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Thats what i call a gearbox!

Wow. Perfect work as always SB. |

|

|

|

|

|

|

#384 | |

|

AF Enthusiast

Thread starter

Join Date: Nov 2008

Location: Norwich

Posts: 671

Thanks: 23

Thanked 116 Times in 91 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Hello again,

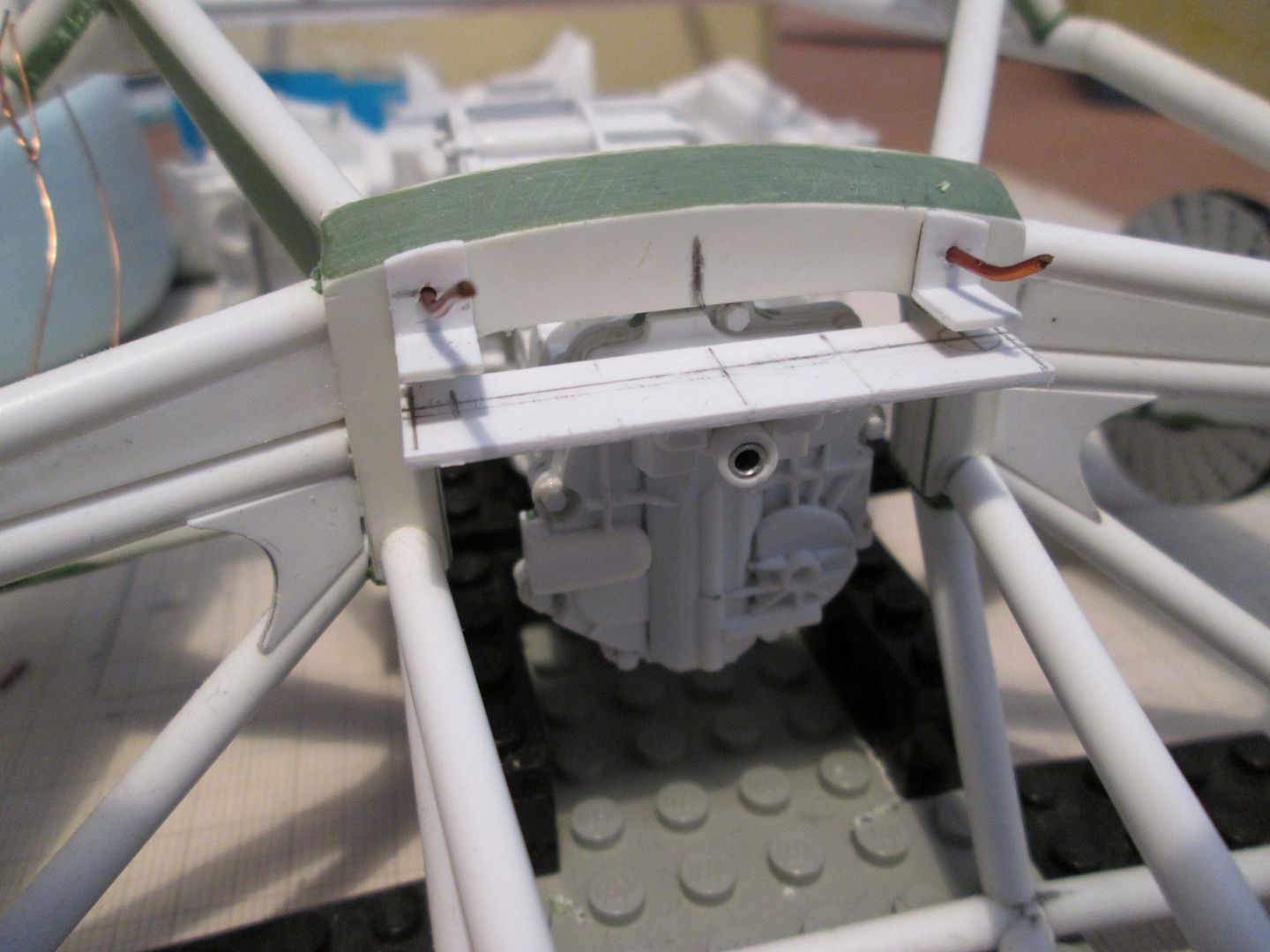

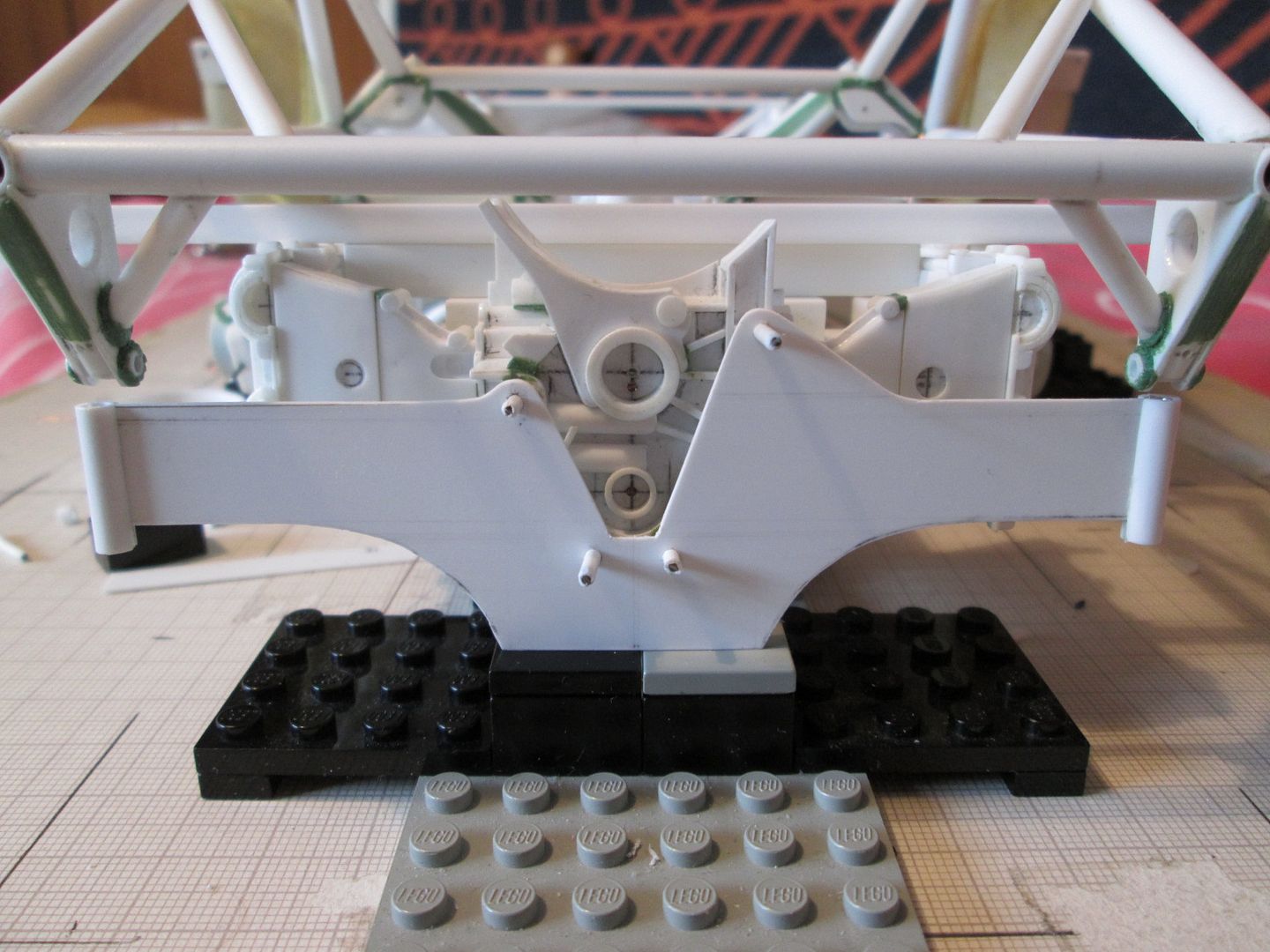

Final stages of the gearbox - for now. There's a few small details to add (clutch lever, pipe fittings, etc) but these can wait until later. It's the sort of stuff that is guaranteed to get knocked off or broken before everything gets assembled into the car! However, I wanted to get the starter motor sorted out, so that's what I've been working on. Firstly, here's a breakdown of the parts:  ...and when it's all in one piece:  I'll add the wiring later in the build, but here's what it looks like on the gearbox:  Providing it doesn't foul the driveshaft when they're added, it should be okay. Returning to the gearbox itself, I added some extra detailing to the end cover and hex-nuts all over the place. You can also see here where I've pinned the front mounting through into the main structure - eventually this will be filled with Greenstuff:  So, with that all done I wanted to start positioning the gearbox in the chassis. The small angle brackets you can see below are styrene with brass reinforcement, which will be pinned through into the chassis beam. The plate across the top of the gearbox is not the final part - I'm considering whether to make this as a styrene / brass sandwich, or whether to add some fibreglass to the mix. Or just to make it from a thin piece of ali...we'll see. I'm tempted to drill into the top of the gearbox and pin through into the underside of the chassis beam, just to give it an extra connection. It would be much easier if the mounting was below the gearbox, but I'm fighting gravity all the time with this one!  More on this next week... Finally...thanks for the positive feedback, guys. Always appreciated, and I'm glad that you're still following along - it doesn't seem like five minutes since I started on the engine during the Christmas holidays, and now it's July and I've got a gearbox sitting here too! The chassis is going to need a good dusting-off before I return to working on it... Yes, the putty I use is 'Greenstuff' from Citadel / Games Workshop. No significant reason, other than it's what I've always used from my figure-painting days (same with the paints, too). I'm always reluctant to start painting at an early stage, preferring to wait until most of the model is ready to assemble. The Citadel paints I use are not exactly hard-wearing (without a coat of varnish, anyway), so anything I painted now would have lots of white patches showing through before too long - particularly on something like the engine or gearbox which are going to get lots of handling. The big disadvantage of working like this is that I'll probably find most of my paints are solid lumps by now, as I haven't used them since I did the 908 in 2011... Getting the ribbing straight is largely down to doing it by eye, although I did use a few offcuts of thicker styrene strip to act as spacers on occasion. The pieces are all pretty short on the gearbox, so it's easy to glue them in without going off-line - if they were much longer I would have to be more careful, as the styrene can flex slightly. As usual, most of this will be hidden from view when the model is assembled, but we all know the detail is there, right?! All the best, SB |

|

|

|

|

|

|

#385 | |

|

AF Enthusiast

Join Date: May 2009

Location: Tucson, Arizona

Posts: 1,469

Thanks: 12

Thanked 126 Times in 120 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

SB - I'm floored with each installment you make

I cannot imagine anyone who has found your threads of your stunning 1/8 builds to NOT continue to follow it to the end of each build. Thanks for explaining your successful ribbing of the gearbox. John |

|

|

|

|

|

|

#386 | |

|

AF Regular

Join Date: Nov 2008

Location: AC

Posts: 118

Thanks: 30

Thanked 21 Times in 11 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

It allways looks like you are dipping the parts into glue, that`s a bad point in your skill, why don`t you change that? Sometime less is a little more in quality

|

|

|

|

|

|

|

#387 | |

|

AF Enthusiast

Thread starter

Join Date: Nov 2008

Location: Norwich

Posts: 671

Thanks: 23

Thanked 116 Times in 91 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Fair point, gp-models. It probably looks worse than it is due to my not-so-great photos, but I know what you're saying. On the smaller parts it's always a pain getting a tiny piece of styrene into the tweezers, then getting it glued properly - I usually add another 'wash' of glue afterwards to make sure it runs into the gaps and cracks. On other areas where I definitely don't want glue overspill I take more care - I don't want it eating into what should be a nice flat, smooth surface! If there's anywhere that the excess glue is likely to cause a problem during the painting stage, I'll give it a tidying with fine wet-and-dry. The other thing I'm considering is using textured paint on areas of some of the parts - engine, gearbox, etc - to try to get some variation in the surface finish.

...but I'll try to improve on this! SB |

|

|

|

|

|

|

#388 | |

|

AF Enthusiast

Join Date: May 2009

Location: Tucson, Arizona

Posts: 1,469

Thanks: 12

Thanked 126 Times in 120 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

SB - do you use glue or solvent weld?

I use solvent weld when I build my "box" models and when modify some bits with styrene John |

|

|

|

|

|

|

#389 | |

|

AF Enthusiast

Thread starter

Join Date: Nov 2008

Location: Norwich

Posts: 671

Thanks: 23

Thanked 116 Times in 91 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Hi John,

For styrene-on-styrene I mainly use Humbrol Liquid Poly glue (which by now is a milky white in colour due to all the dissolved plastic in it, rather than the original clear!). If it's something more structural, or fibreglass, I'll use CA - currently a fresh bottle of Vitalbond Thin. I'm not familiar with Solvent Weld, but I'll keep an eye out for it. SB |

|

|

|

|

|

|

#390 | |

|

AF Enthusiast

Thread starter

Join Date: Nov 2008

Location: Norwich

Posts: 671

Thanks: 23

Thanked 116 Times in 91 Posts

|

Re: 1/8 Porsche 935/78 'Moby Dick'

Hello again,

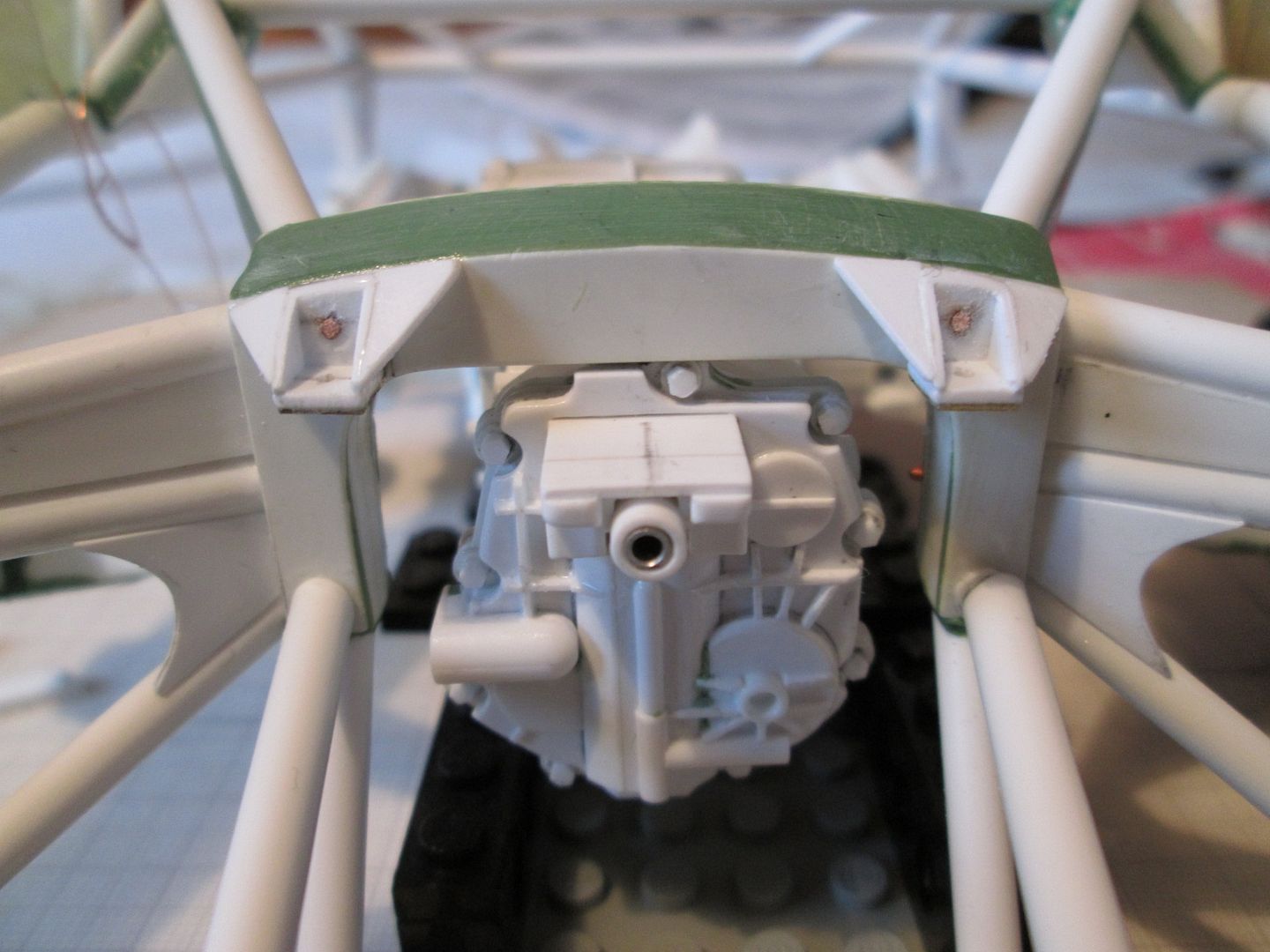

First up tonight, I've added some reinforcing plates to the angle brackets of the front gearbox mounting:  You can't see it here, but I have drilled and pinned the top of the gearbox into the underside of the crossbeam. This is making life so much easier as it gives me at least one fixed point whilst I work on the rear mountings, plus it will hopefully take some of the strain out of the 'official' front mounting. Next, I started work on the two main engine mountings at the back. The problem again is that all the weight is hanging down, so a simple piece of chassis bracketry becomes an exercise in getting as many solid joints as possible into a small part! You can see below how it starts as two short pieces of 1/8" tube:  The round tube in the centre will allow me to create the look of a pair of swaged holes, plus it also puts strength into the core of the bracket. I'll pin the engine mounting plate straight into the vertical tube section, and disguise the joint. A second side plate and another tube stay complete each bracket, ready to be pinned into place beneath the engine bay:  In this final photo you can see the two brackets fitted to the frame, plus I've started adding greenstuff to fill the joints. The mounting plate across the back of the engine is currently 0.75mm styrene sheet - this is not necessarily the final shape, but it will allow me to continue the build. A little bit of flex might actually be a good thing - the engine assembly shouldn't be able to move around too much as the pinned joint at the front won't allow it.  The two tubes at the far ends are a styrene outer, with an ali core. The styrene is cut along the length to create a slit so it clamps onto the engine plate - this joint is likely to be the weak link in the whole assembly, so I need to get as much strength into it as I can. The four pins in the middle go straight through into the back of the engine, so that's all solid. The fun (ie. time-consuming) part in all this has been getting the engine to sit level while playing around with the mounting; at the time of this photo it was still slightly askew - the outer chassis brackets are level with the baseplate, but the length of styrene box-section laid across the top of the engine is oh-so-slightly off. I've now got it just about where I want it... So, the project continues. Now I've got the rear brackets in place I can make the frames which extend out the back to mount the tail section of the bodywork, plus the outriggers which support the wheelarches. I think the driveshafts will be underway soon, too. Starting to detail the top of the engine will probably be a job for my holiday week, so that I can really get into it... All the best, SB |

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||

|

POST REPLY TO THIS THREAD |

|

|

|