|

|

| Search | Car Forums | Gallery | Articles | Helper | Air Dried Beef Dog Food | IgorSushko.com | Corporate |

|

|||||||

| WIP - Motorsports Post topics for any "Work In Process" motorsports vehicles in this sub-forum. |

|

Show Printable Version | Show Printable Version |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

#31

|

||||

|

||||

|

Re: Jordan 191

Cheers for the info Jaykay.

If it's any consolation I still have to clean up the faces of the nuts sometimes when I'm using a three or four blade end mill. Probably a combination of me not getting the correct rpm v feed speed...loads to learn still!

|

|

#32

|

|||

|

|||

|

Re: Jordan 191

Hi, here’s some more progress :-)

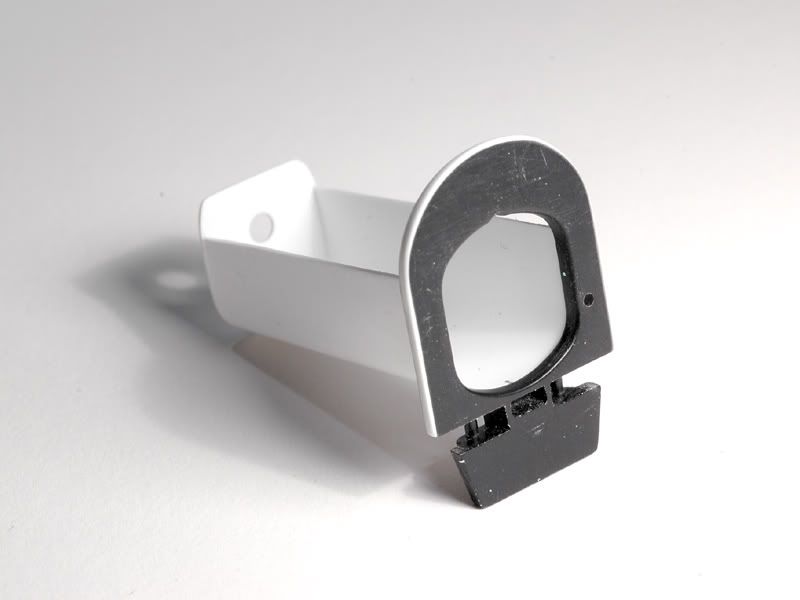

This may not look as impressive as the turned and milled parts i showed you last time but in fact it was more time consuming and trickier because most of it had to be done by hand with test fitting and checking over and over again. Anyway….here we go. Before I can go about and build the suspension I had to put the front of the monocoque together. The part I made to house the front damper needed a further addition with these channels. The pushrods will run through them.  The next part is the front bulkhead of the monocoque. I want to make the nosecone removable so I try to build it like the real one. I photo etched a frame with the holes for the mounting pins of the nose and a corresponding frame piece that goes on the nosecone to get everything aligned properly. I doubled up the etched frame with styrene because I can’t etch it in the correct thickness.  Next you can see the two pieces mounted on the monocoque. Of course I shortened the monocoque by the thickness of the new bulkhead before adding it to keep the original length :-)  At the same time I made another piece that won’t be visible at a first glance but I find it important. That’s the inside of the monocoque with the dashboard bulkhead.  The black dashboard piece is from the kit. I sanded off some details and then added a thin styrene strip on the outside because there was a gap with the monocoque when it was in place. Tamiya just left a big hole where the driver’s legs would go that would leave the suspension arms visible, so I added a tub that will cover them and also take up the pedals and steering column. The part can easily be slid in from the cockpit during final assembly. Here you can see it dry fit with the rest of the cockpit.  So on to the nosecone with front wing. Here you have the original kit pieces:  I cut the flaps off the wing ( they will be replaced ), glued it to the nosecone and after filling up some holes and gaps sanded all the surfaces. Then I added the photo etched frame bit and some styrene that corresponds to the monocoque front bulkhead I made.  And finally here is the nosecone held to the monocoque with two 0,5mm pins and I keep my fingers crossed that this will still fit after paint and decals :-)  So much for now and thanks for checking! |

|

#33

|

||||

|

||||

|

Re: Jordan 191

Wow! That's about the only comment I can make when viewing your builds! You should consider writing a book that details some of your builds from start to finish! It'd be a best seller as far as hobby books are concerned.

__________________

Rob

|

|

#35

|

||||

|

||||

|

Re: Jordan 191

Insane! (in teh good way

) )Quote:

__________________

Guideline for happy modeling: Practice on scrap. Always try something new. Less is more. "I have a plan so cunning, you could put a tail on it and call it a weasel" - Edmund Blackadder |

|

#36

|

||||

|

||||

|

Re: Jordan 191

Robi |

|

#37

|

||||

|

||||

|

Re: Jordan 191

Ok, big-jay. Another question (yes, I'm trying to thieve your secrets

): ):What kind of thinner do you use for the polyester putty? Thanks so much. Last edited by maxone; 01-27-2010 at 10:55 AM. |

|

#38

|

||||

|

||||

|

Re: Jordan 191

Yikes! Some seriously impressive turning and etching going on in this thread. Can't wait to see more.

|

|

#39

|

|||

|

|||

|

Re: Jordan 191

Guys, thanks again :-) This build report is my "modeling book". I also doubt too many people would buy a book like that. Ask modeling magazines how many copies they sell these days. I think the WEB is a very good tool to do this but once i'm done with this build i think i will make one book for myself from the build report :-)

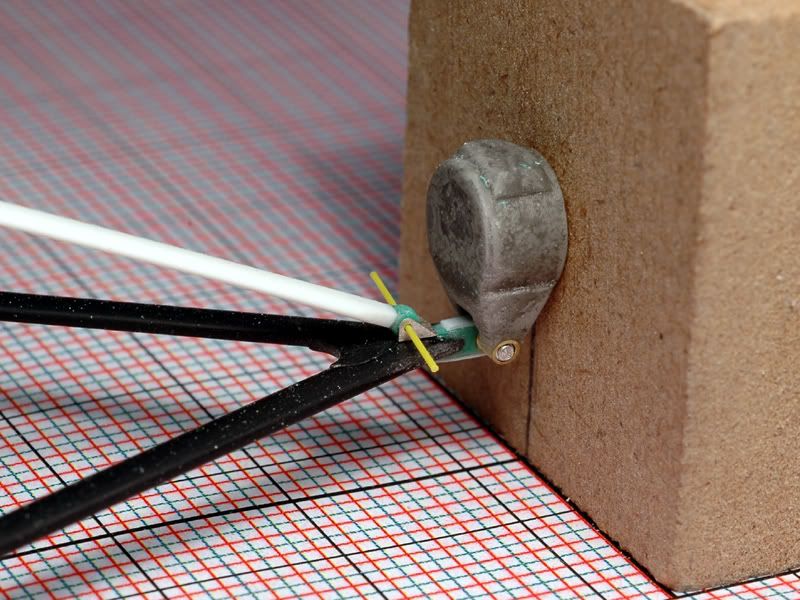

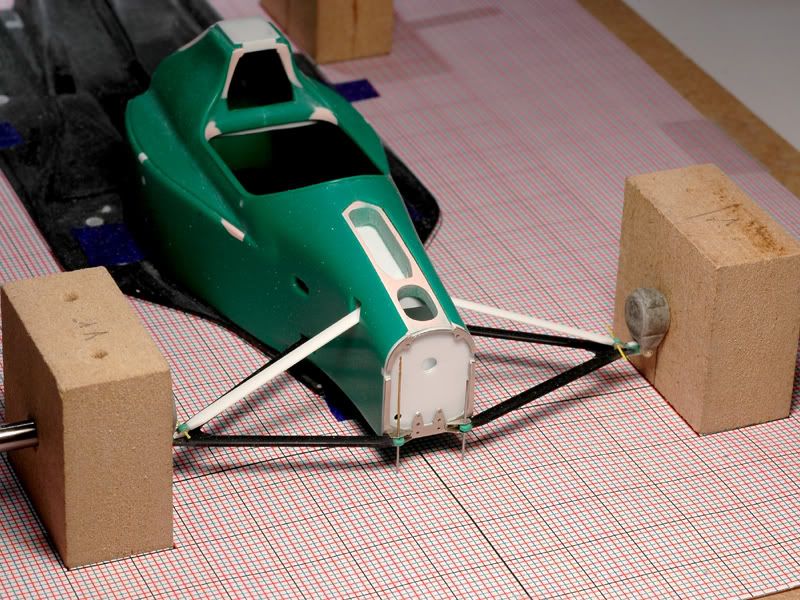

maxone... i use ordinary nitro thinner for the putty ( ZERO thinner works also ). I mix it with some of the white putty until i have the right viscosity and then add the red hardener. The thinner may slow the drying though. Anyway, time for some more build progress. I carried on working at the front end of the car. It was time for the suspension arms. I had to rework the lower front arms substantially. While I kept the rear chassis “connector” from Tamiya I had to change the one at the front because that will now be visible with the removable nose cone and should look like the original. Also the outer one had to be remade to connect to my new upright. I had to guess a bit because I don’t have enough pictures of that area but it seems to be the same sort of connection the McLaren MP4/4 has at the top of the front uprights so I built it accordingly.  I used brass tubes for better strength and the little silver part is turned from aluminium. The white part is the pushrod I scratch built from 1mm sheet styrene, because the kit ones weren’t long enough. That’s because the connection points of the suspension arms to the uprights are too close to the chassis on the kit parts. I made mine more like the real ones so the pushrods ended up being a bit short to later connect them to the front damper in the nose. I could have tried to extend the kit parts but making new ones wasn’t really more work. Next you see the arms held in place to the monocoque with two 0,4mm drills on photo etched brackets I made. In the etched frame on the monocoque I also made two cutouts where the steering mechanism will later go.  On the outside you have the arm connected to the upright which is held on the jig. The upright is connected to the arm with another etched bracket.  Finally here’s an overview with both sides dry mounted.  The jig was a really good thing to build. It doesn’t speed up the build but makes it more precise. Only because I had it for reference, did I notice that the lower arms were about 0,5mm too wide in the beginning. That sounds very small but 0,5mm in the wrong place can really screw the whole suspension geometry and make the car sit wrong in the end. Now I will have to do the upper arms and steering arms which will be at least as much work... Because I was a bit annoyed with the suspension arms I also started working on the brake ducts. In the kit they are typically for Tamiya an integral part of the upright as I showed you previously. Mine are separate for ease of painting and decaling and simply because they’re like that on the real car :-) I used the kit parts, thinned them out from the inside and then closed the channels with sheet styrene and added the shapes that connect them to the upright and funnel the air with more styrene sheet a turned bit of renshape and some polyester putty. Here are two views of the left side duct. Now I have to make a symmetric one for the right side….:-)  So much for now and thanks for looking! |

|

#40

|

||||

|

||||

|

Re: Jordan 191

You are my hero man. I don't care if you ever paint a part, I could watch you work all day!

Awesome...... Clay

__________________

http://public.fotki.com/ClayK/ |

|

#41

|

||||

|

||||

|

Re: Jordan 191

Lucky times! Two of my preferred AF heroes! Few days ago Dennis back with a jewel and now Jay is showing how much fun he's feeling and how HI he's able to pull the bar.

How to say... fantastic, one of those thread that make you back to your own desk immediatly. Your contribution to community's knowledge and motivation is HUGE!

__________________

gio gio

|

|

#42

|

||||

|

||||

|

Re: Jordan 191

Quote:

JayKay, I always read your updates with a huge smile on my face. Entrancing work

__________________

Guideline for happy modeling: Practice on scrap. Always try something new. Less is more. "I have a plan so cunning, you could put a tail on it and call it a weasel" - Edmund Blackadder |

|

#43

|

||||

|

||||

|

Re: Jordan 191

Beautiful work JayKay. Your parts are so incredibly clean and precise. I cant wait to see more progress!

__________________

-Mike AF Director of Media / Photographer  [email protected] | AutomotiveForums.com | Flickr Gallery |

|

#44

|

||||

|

||||

|

Re: Jordan 191

Exquisite work! It really shows what can be done with top-class planning and execution.

__________________

Mark R |

|

#45

|

||||

|

||||

|

Re: Jordan 191

Thank you jay, I'll try nitro with polyester putty. Ok: mine It's not white, but I hope nitro will works anyway

|

|

|

POST REPLY TO THIS THREAD |

|

|

|