As i'm working on these for my Celica, I thought i will put together a specific 'how-to' for future reference.

Cutting away the polycap housing is the first step, which is not easy without some sort of motor tool. A steel cutter is used for the job by steadily grinding away with the tip. Take it easy here and watch out for the cutter biting into the plastic, when this happens it will jolt and will usually damage a spoke. You will notice a small recess when the housing is removed, this is what will be used to fit the peg into.

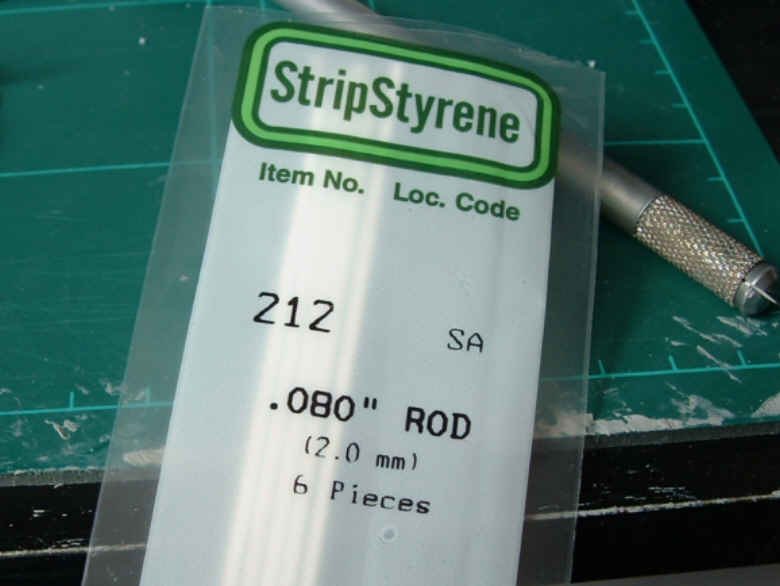

The pegs can be taken from a Fujimi kit but chances are you won't have any, so we'll make some. 2mm styrene rod is what i'm using for this, 2mm seems to be the standard for the pegs on most rims.

The recess on the rims has a larger diameter than 2mm so you will need to widden one end of your peg to get a tight fit. By far the easiest way of doing this is to use heat and soften the tip, then press the rod onto a hard flat surface. Try to keep it as straight as possible, you could from some kind of jig but dont worry coz you can always sand the base flat.

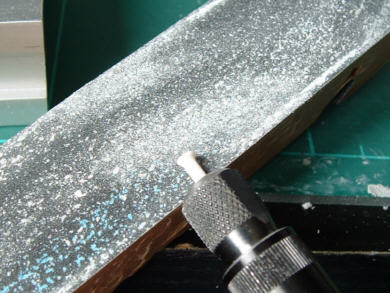

Sizing the base is a job for the Dremel again, fit the peg straight into the chuck of the drill and use a sanding block or file. Apply light pressure and check the fitment to the rim regularly coz you want this to be a very tight fit. In the case of this how-to, i'm using 17" rims which have a smaller recess than the 18"s, so the base on these pegs is barely noticeable but necessary all the same.

Use your choice of glue to attach the pegs, i've gone for styrene adhesive coz this will weld the join together and should provide a stronger bond than CA coz of the small area we're dealing with. Either way these are still fragile so fitting and removing them to their hubs should be kept to a minimum. If you have followed everything so far by keeping a tight fit and a flat base, the pegs should stand at 90degrees and u won't have wonky rims

This is infact another reason why strene adhesive is better here, coz u will have time to play with the allignment.

Do this 3 more times, cut the pegs to length and you're done

Hope u all find this useful.