Technically, you are correct about the seals, but they should NOT come out without intentionally picking them out.

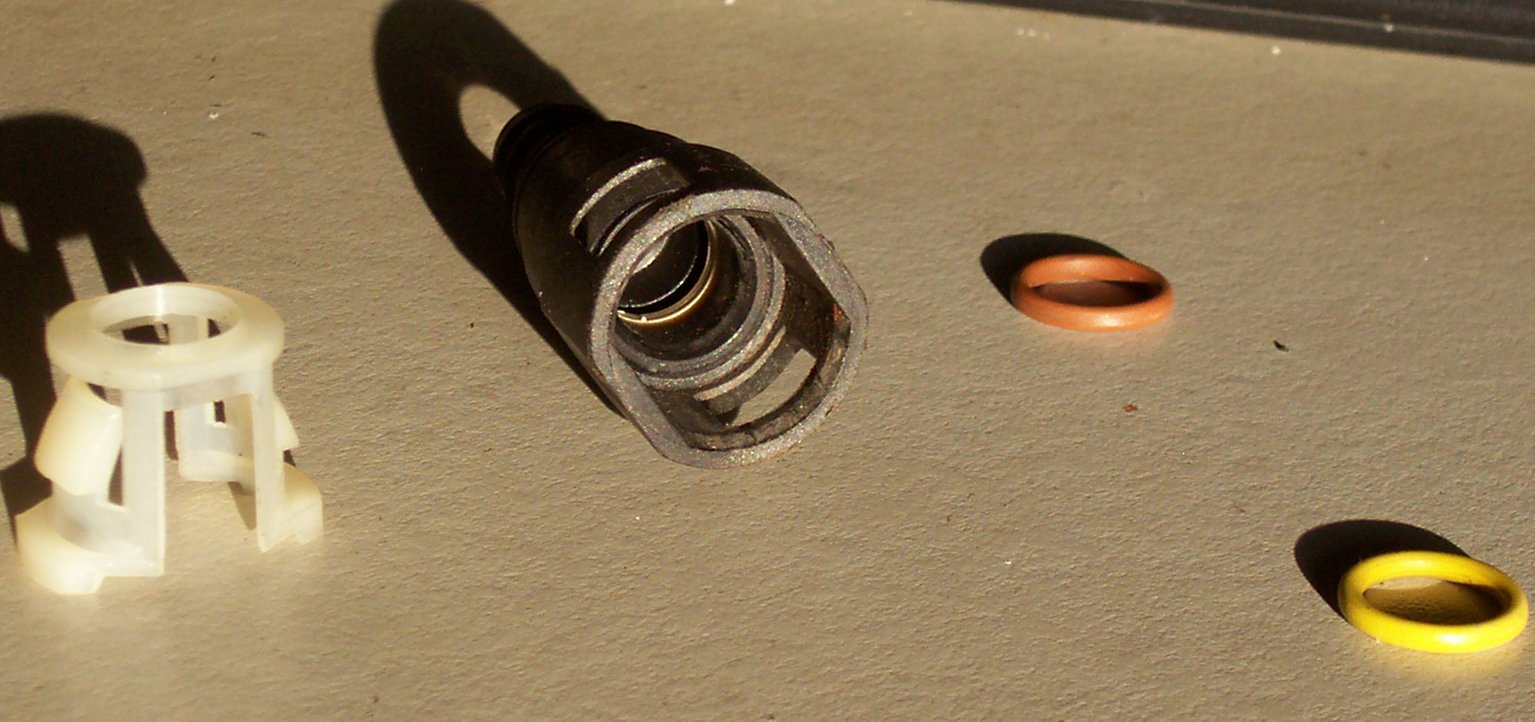

The deepest is an FKM (Viton) O-ring followed by a PE guide ring, followed by a silicone O-ring, and finally a UHMW (Nylon) sleeve/bushing/clip nearest the fitting opening. If these are damaged, the potential for leaks exist. The steel standpipe which slides into the fitting must also be clean, free of rust, not distorted, and it helps to apply a bit of clean engine oil to aid in insertion. The oil will not negatively affect any of the materials.

If the connections are not clean, sound, and smooth, there is little chance of them sealing. The hose fitting can be replaced, but it requires special procedures including warming the hard nylon hose to a controlled temperature, supporting the hose in a round clamp (like a flare tool line clamp) to prevent kinking, then inserting the new barbed fitting straight and quickly. Of course, there must be enough line length available to accomplish this and still connect the filter.