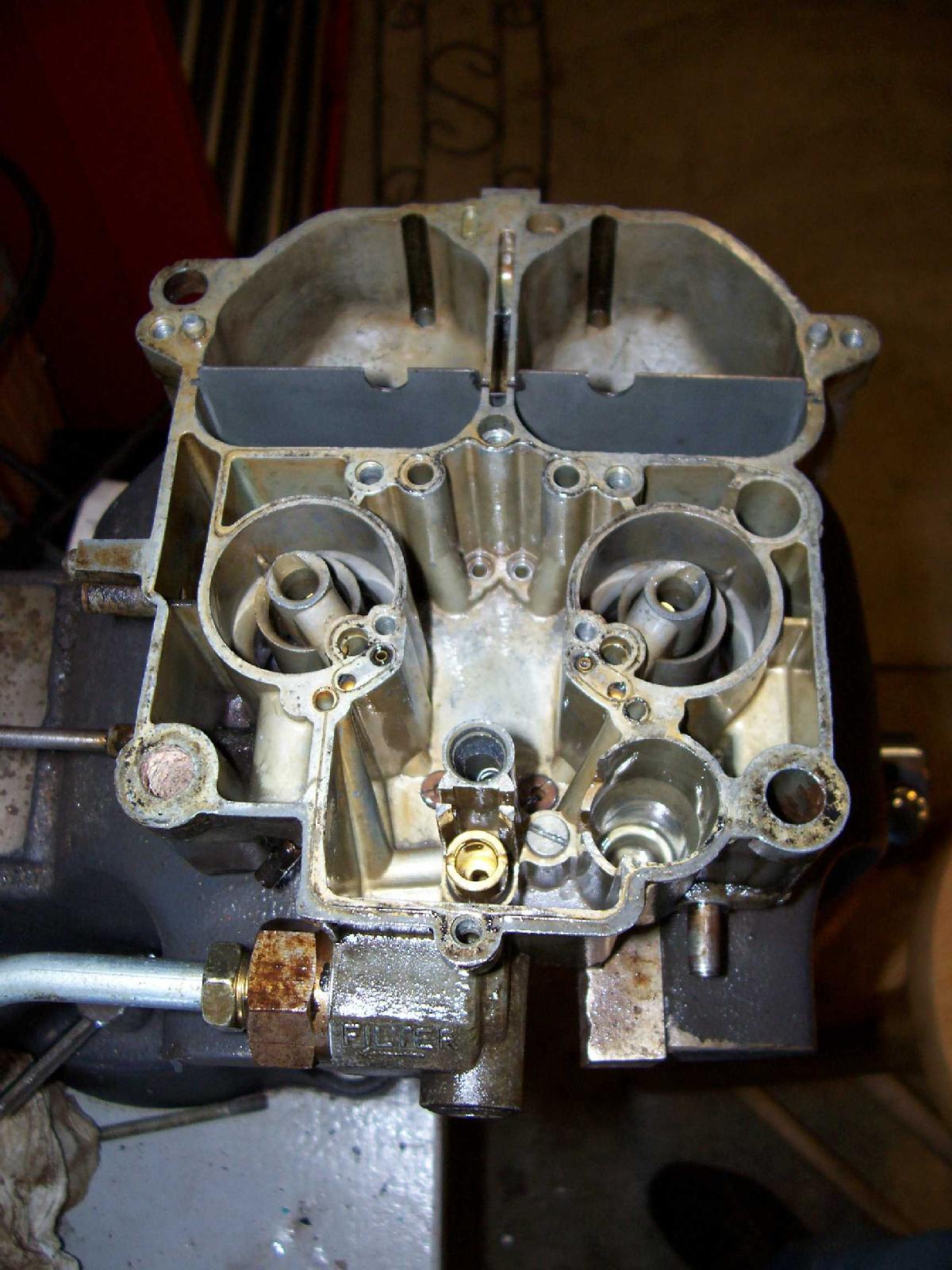

There is a little distortion on the secondary venturis, but the larger depressions shown in the photos are created at the factory when the fuel passages are angle-drilled through the venturi supports, just like every other 4MV/4MC/E4ME:

Blt is correct about the throttle shaft bushings. They are common wear points and are easy to repair. Remove the throttle body from the bowl. This will entail removing the bowl cover, linkages, and various assemblies and bits.

You'll need a few odd special tools like reamers:

Remove the throttle plate springs and secondary lockout pawl.

Carefully remove the throttle plate screws. They are staked, so it will take a lot of patience, a proper fit of the driver, and several applications of lubricant and reversing direction to prevent thread damage.

Note the orientation of the throttle plates and remove them. Slide the throttle shaft out of the throttle body.

Measure the length of the repair bushing and ream the body to the proper depth.

Verify the correct depth of the ream to avoid unnecessarily breaking through the throttle bore side, potentially causing throttle plate binding problems.

Drive the bushing into place.

Finish ream the bushing to the correct throttle shaft diameter.

Reassemble the throttle plates, links, and springs.

This would also be a good time to seal the Welch plugs in the metering wells on the bottom of the bowl. Both the main and secondary metering well plugs on the underside of the main carburetor body are known problem areas. Any fuel leaking there goes directly into the intake and can significantly enrich the mixture, drain the bowl after shut down, and cause flooding and hard starting. These can be cleaned off, peinned closed, and covered with a fuel-resistant epoxy to seal them against fuel leakage.

Clean the areas, make sure the Welch plugs are securely staked in place, and apply a fuel resistant epoxy to seal over the plugs: