Update:

OK, so the PE hinge idea is out the window, I didn't have a clue how difficult it would be PE .020 stainless steel.

I still plan on utilizing working hinges with posable struts, I'll just have to go another route. Thanks to GTMike40 and Ferrari TR for helping me sort this out...

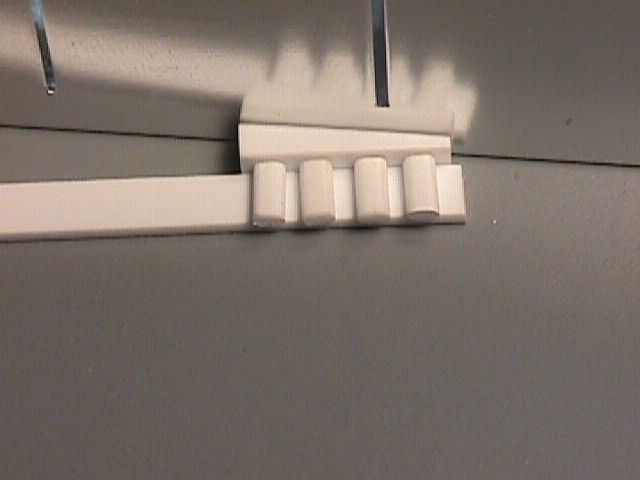

Cut the runners for the Magnus Motorsports sheet metal intake, nothing huge. They still need to be cut to the exact length, have the ends squared, the flange end tapered (although with a fule rail and N20 system in the way I dunno if I'll go through the trouble), and a flange built. Oh yeah, and add welding lines

Here is the throttle body I'm building for it. This is a first generation 4G63 TB instead of the 2nd gen, because the 1g was a 60mm while the 2g was a 52mm. Enough to make a difference...

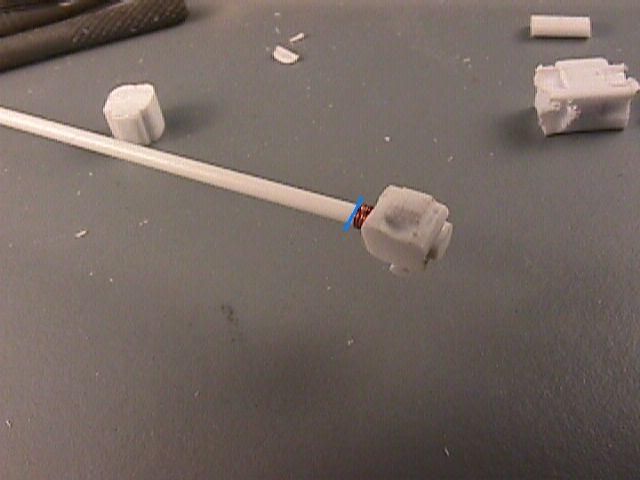

Chunk of styrene rod filed down to rough shape.

This is after filing, sanding, drilling, Dremeling, and gluing

Man, I hate this camera, I think I might go splurge and get something with at least 5 megapixels... You can't see anything really. The 4 black dots are for vacuum lines that will run to firewall solenoids. The blue dots are for screws (one the Base Idle Set Screw). The green square is where the coolant passage is, it will connect to the water line running underneath it. The red square is the abse of the Throttle Position Sensor, I'll add a chunk of styrene with some wiring that hooks up to the wiring harness...

This is from the other side, you can see the throttle shaft with a wire winding. I'll cut it off at the blue line and add a disk of styrene and the throttle cable:

Still needs some finishing work and a primer coat to pick up defects. It looks a tad large next to the manifold, but scaled out it's only about 2.75 inches, which seems reasonable.