More progress over the weekend:-)

I started to work on the seat. This is the piece that comes in the kit:

It's supposed to look a bit more like this:

First of all the molded in seatbelt had to go ( rotary tool, files and sandpaper ) and then it needed some shape around the legs!

I put styrene strips on the sides and the middle, then shaped the edges and filled them up with polyester putty. With more filing and sanding i got the right surface and then drilled and filed holes for the lower seatbelts and some cables. These are also thinned out from the rear to get the material very thin at the holes' edges. Now it needs some primer.

I also changed the armrest again....got the rear end wrong the first time:-( It still needs a little cutout near the gearstick and the insert bit.

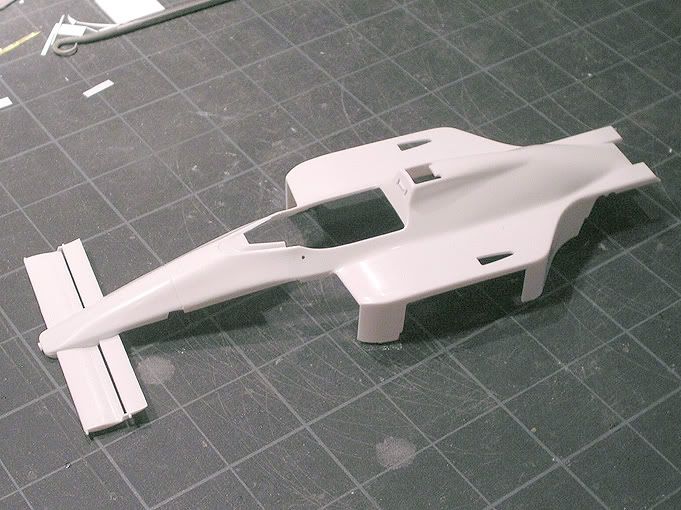

I then decided to attack the cowling. The kit part comes like this:

Generally speaking it's not bad but needs some work all over. I started by closing the holes for the turbo air intakes on the sidepods and the mirror holes with bits of styrene and then sanding all outer surfaces to get them straight. Below the front wing i closed some holes ( wonder what they were meant for in the first place....) and ejection marks and sanded the wing elements. The trailing edges needed some thinning and i cut of a little piece of plastic that connected the flaps on each side. That will later be replaced with PE.

Then started the really annoying part....thinning the whole cowling. Due to the injection molding process all the walls are way too thick for that scale ( like on the undertray before ) but instead of replacing the only choice here is "dremeling", filing and sanding. The inside of this cowling is not very clean anyway. You can see there's been some serious improvement in mold making during the last 15 years:-)

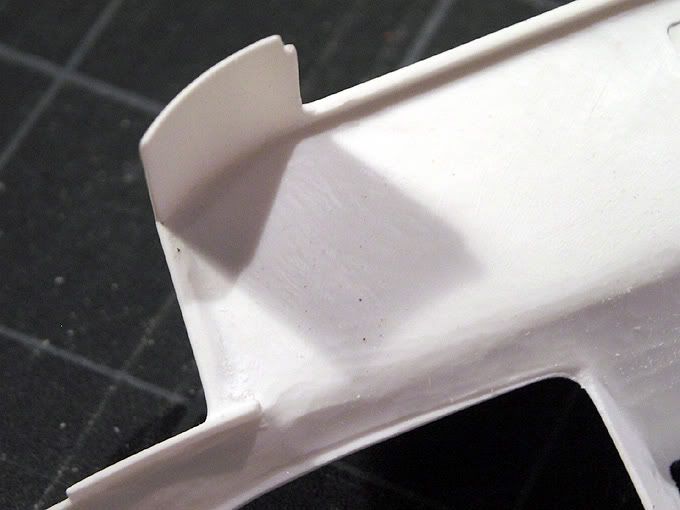

It's a bit difficult to show here ( especially on this white piece ) but this is one of the sidewalls before treatment:

....and this is another corner afterwards.

I try to get the walls quite thin especially where it's very obvious ( to around 0,5mm - 0,7mm ) because that looks better and helps with space when i add details later. With several layers of paint and decals in some areas they'll grow some "fat" later on anyway. The material stays pretty strong but it's a major league p.i.t.a. to work on. Resin is nicer in that respect but it breaks more easily of course.

So much about this. I have another couple of hours to file and sand along and you wont see much of that in a photo but it needs to be done:-)

I figured i have to do it now before i start scratchbuilding the sidepods and putting the engine to get the height correct....

Also i have to get the cowling and the monocoque alligned before i get into the internals!

Jaykay