|

| Search | Car Forums | Gallery | Articles | Helper | AF 350Z | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|||||||

| Machine Tools Learn about metal lathes, milling machines and CNC tools. |

|

Show Printable Version | Show Printable Version |  Email this Page | Email this Page |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

|

#61 | |

|

Authorized Vendor

|

Re: Machining Discussion-Lathes, Mills, CNC.

Andy, he's all your

opcorn: opcorn:  @jbain: chuck crap over other member's thought isn't the style of this forum. I own one of those 60Kg. lathes branded Einhell (the same as some UK branded lathe) and made (I guess) in china and I haven't the impression of a great tool, despite the weight LOL. It's also true that I havent rebuilt like suggested on minimill...., too lazy to do it, but may be now, after a couple years.. I'll play a bit with my lathe's screws

__________________

gio gio

|

|

|

|

|

|

#62 | ||

|

AF Fanatic

|

Re: Machining Discussion-Lathes, Mills, CNC.

Quote:

And BTW it's "misinformation" NOT Miss-Information - unless you had a some sort of beauty pageant in mind....

__________________

Guideline for happy modeling: Practice on scrap. Always try something new. Less is more. "I have a plan so cunning, you could put a tail on it and call it a weasel" - Edmund Blackadder |

||

|

|

|

|

#63 | ||

|

AF Newbie

Join Date: Aug 2007

Location: melbourne

Posts: 20

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

Quote:

He stated his opinion, " and it almost goes without saying that if it comes from Harbour Fright, it is the wrong machine. Everything I have ever heard regarding their machine tools is to avoid them like the plague- they are worth no consideration at all". I just stated my opinion. Aren't you allowed to state your opinion, if it clashes with someone elses? What is this forum meant to be used for then? I did not personally insult him, so what' all this about then? @jbain: chuck crap over other member's thought isn't the style of this forum. I just stated what my experiances have been with smaller machinery and then with larger machines. |

||

|

|

|

|

#64 | ||

|

AF Fanatic

|

Re: Machining Discussion-Lathes, Mills, CNC.

Quote:

Then there were the first 2 sentences of your post which (to me) as read as being pretty personal in nature. Of course you are supposed to express opinions - especially when they differ from someone else's - that's how we all benefit from forums. IMHO what you wrote didn't seem like an opinion but more like a criticism of MPWR for him having his opinion. But maybe that's just my interpretation. Internet communication is a fragile thing and misunderstandings are easy and frequent which is why it's always a good idea to think about what and how you are writing - especially when directed at someone who has a 5-star record on AF of providing abundant, well informed and reliable advice on subjects he knows quite a lot about. My  PS I think Harbor Fright is a GREAT way to call Harbor Freight - almost as good as Image Hovel

__________________

Guideline for happy modeling: Practice on scrap. Always try something new. Less is more. "I have a plan so cunning, you could put a tail on it and call it a weasel" - Edmund Blackadder |

||

|

|

|

|

#65 | ||

|

AF Enthusiast

Join Date: Jul 2004

Location: Taipei

Posts: 781

Thanks: 0

Thanked 2 Times in 2 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

@Jbain This is what I took of your post. Meaning that underneath all the words this is the message that I thought you were trying to send. Quote:

__________________

Please read the following linked articals before posting a question. Once you have and still have questions, try to post your questions clearly. This will make a lot of people's blood pressure drop back to normal, including mine.  NEW TO THE AF MODELLING FORUM? PLEASE READ THIS FIRST AF Car Modeling Tutorial, How-To and Product Review Depository AF Car Modeling Frequently Asked Questions [FAQ] - * Look here first! * ver2.0 And finally,I wish you all happy modeling

|

||

|

|

|

|

#66 | |

|

Captain Over Engineer

|

Re: Machining Discussion-Lathes, Mills, CNC.

Ok, this is going to get out of control. Keep it civilized or I will start moderating. There's a whole respect issue we have here on the forum, that is not being seen.

Jbain, you weren't just expressing your opinion on why the Chinese lathe was better, but you went out of your way to disparage the Sherline lathe. I could just as easily, destroy what you said about the Chinese lathes the way you attempted to blur the image of the Sherline. That is, if I wanted to turn this into some sort of competition thread, but that is NOT what this is about. So further on, keep it as an information thread. Not a thread about who's lathe is better. If your lathe is better, please don't brag about it, just state why you feel it is better, and post the numbers that prove it is better (tolerance, run-out, etc). Thanks.

__________________

-Mike AF Director of Media / Photographer  mike.lawrence@automotiveforums.com | AutomotiveForums.com | Flickr Gallery |

|

|

|

|

|

#67 | ||

|

Image Hosting Exceeded

Join Date: May 2003

Location: Flying in circles

Posts: 4,233

Thanks: 23

Thanked 95 Times in 86 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

Quote:

Welcome to AF. You are of course absolutely welcome to express nearly any opinion you like here, be it contrary or complementary to others expressed here. But I wonder if you mean to come across with quite so much agression? I believe the point that Klutz_100 and Gionc were making was that the tone of conversation in this forum tends to keep to friendly conversational- and that's maybe not exactly how you're coming across. I'm fairly well aquainted with Harbour Freight. My local one is just a few miles down the road, and I'm in there pretty regularly- it's about the only close place I can buy anything related to machining retail. I've got a drawer full of carbide tipped lathe cutting tools and the like from there, as well as a bench grinder, band saw, and other odds and ends. My god is that band saw a sorry piece of sh!t quality wise, but it does the job and until it kills me I've saved at least $100. I learned machining on full size industrial machines- non CNC Bridgeport mills and South Bend lathes. From working on them I certainly expect any machine tool I use to be able to repreatably cut to 0.0001" out of the box with any reasonable measure of competence from the operator. I've never been impressed with any of the machine tools I've seen at Harbour Freight. When by turning a handwheel I can feel slop (not backlash!) in the leadscrew, or play in the cross slide sadle, it's easy for me to tell that this is not a machine I want to use. Of course, this is just my opinion from my observations. I've certainly heard that Chinese made tooling can be rebuilt by a competent and patient machinist into useful gear. If saving money and rebuilding to your own standards are your thing, more power to you. There's a great tradition amongst machinists of improving one's tools. But personally when I've bought tools, I've bought them for projects, not to be projects. I believe you're the first person I've heard say that they're really satisfied with a tool purchased from Harbour Freight. Are Sherline tools toys? A Sherline mill compares to a Bridgeport mill in exactly the way an Iwata Revolution compares to a top end automotive spray gun. They're simply the finest tools availible for their intended tasks. Are they expensive? No doubt. Are they small? Certainly- and if you work on larger projects, than obviously you need bigger tooling. But the fact that Toyota doesn't use Iwata airbrushes in their factories to paint full size cars does not make them toys, does it? If you take a look at or try out Sherline gear, you may find it has less aluminum than you think. I frequently use magnetic tool bases with my setup.

__________________

PHOTOBUCKET SUCKS |

||

|

|

|

|

#68 | |

|

Vendor

Join Date: Nov 2005

Location: Malaga

Posts: 241

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

I didn't think that taking this thread to the first page would start this discussion.

Anyone could give me some advice about I asked in the previous page? Thanks. |

|

|

|

|

|

#69 | |

|

AF Enthusiast

Join Date: Oct 2004

Location: H.B., California

Posts: 3,531

Thanks: 11

Thanked 101 Times in 96 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

jbain,

With the passion and experience you must have according to your posts, maybe you could show us some of the wonderful high-tolerance work you've been able to produce with what many of us think are sub-standard machines? If they can do what you say, I'm sure there are a lot of people here who would like to know how you were able to make them work to your benefit. Did you get a "good" one where all the ones I've seen were poorly built examples with lot's of slop? These are viable logical questions. I have played with some of the Chinese machines, and they will not do what I need of them, but the Sherline is a very economical alternative in my opinion. Yes, they may cost more at the time of purchase than a Harbor Freight import, but all said and done, to fully outfit the two side by side, you will end up saving money with the Sherline. At least it worked out that way for me. Plus I'll bet the Sherline will be running twenty years down the road and the HF stuff won't be alive after five to seven years, let alone in tolerance. And Sherline is there with support, (I'll bet in twenty years still too), not something I've been able to get from my local HF store. "You bought it, deal with it" is their attitude. A picture is worth a thousand words. And I'd be glad to show what I've been able to do with what you call a toy, Sherline set-up, (as if I haven't shown a bunch already)... No, I do not work for Sherline, but I am a very happy owner of Sherline products. I did my homework before purchasing, and am being rewarded for it with a quality product. And keep this civil please. This should be a discussion for enlightening others who are looking to get into machining, especially at an economic level. Moderate away if needed Mike... - Mark |

|

|

|

|

|

#70 | ||

|

Captain Over Engineer

|

Re: Machining Discussion-Lathes, Mills, CNC.

Quote:

I'm willing to bet it wont have the accuracy of the Sherline lathes, but it will probably do a fair job. Gio uses a version of a Sieg (chinese) lathe and he turns out some pretty nice work, I do know that he has run into precision problems for super tiny parts though. (Correct me if I'm wrong Gio.) If you're have tight tolerances and accuracy, it wont do the job most likely. But if you're after ornamentation and fair tolerances it should work. This is almost an extension of the debate we're having now Sieg vs. Sherline. Hope that helps.

__________________

-Mike AF Director of Media / Photographer  mike.lawrence@automotiveforums.com | AutomotiveForums.com | Flickr Gallery |

||

|

|

|

|

#71 | |

|

Authorized Vendor

|

Re: Machining Discussion-Lathes, Mills, CNC.

Yep Mike, correct, but my stuff is absolutely equal to Steve's Clarke, simply I guess they're the same product re-branded. Also some problems was fixed over the time so I guess 50-70% was lack of skills at begin

__________________

gio gio

|

|

|

|

|

|

#72 | |

|

AF Enthusiast

Join Date: Jul 2005

Location: London

Posts: 899

Thanks: 3

Thanked 11 Times in 10 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

I've got the Clarke too and I'm happy with it - it does everything I want it to do, to a good standard. I do have to be prepared to make adjustments now and then. A lot of the previously mentioned 'slop' can be tuned out with patient adjustment - all the examples that I tried in-store were woefully out of adjustment, but it's nothing that a day's tear down won't rectify. Some may say this is not acceptable in a few hundred dollar machine but to me it's all part of the lathe learning curve and is an enjoyable process to boot, and after two years mine performs far better than when I took it out the box.

I read up on these machines before I purchased. I remember on one particular site a guy was using his to machine rifle barrels - if it's capable of that then it's fine by me!  |

|

|

|

|

|

#73 | |

|

AF Newbie

Join Date: Jun 2007

Location: northampton

Posts: 47

Thanks: 1

Thanked 0 Times in 0 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

Hi my name is Dan, I am new to this forum and very impressed with what a lot of guys and gals have done,

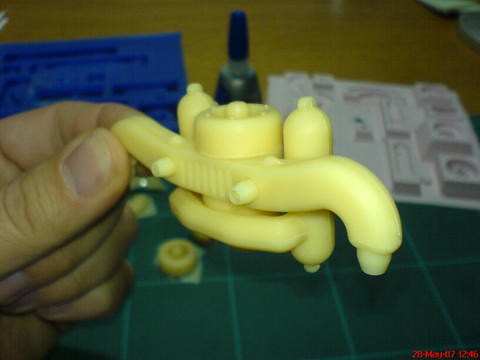

on an alternative to mill and lathe setups I thought a Roland Modela MDX-15/20 desktop subtractive rapid prototyping machine(small cnc mill) would be an interesting choice, you have to give it 3D data to work so you will need a solid modeling program but you can do some pretty neat stuff with it, there are limitations as with other machining setups but getting around them is part of the ingenuity, hopefully in the future I will get a small lathe to compliment this machine or a fourth axis here are a couple of pictures of the machine and things I have made with it  Machinable blue wax Machinable blue wax Polyurathane resin Polyurathane resin Start of my jetpack model Start of my jetpack model silocone RTV mold silocone RTV mold MDX-20 in its box MDX-20 in its boxManaged to get the pictures back, suppose I must read up on how to post pics properly Last edited by PlutoniumDan; 09-13-2007 at 03:35 PM. |

|

|

|

|

|

#74 | |

|

AF Fanatic

|

Re: Machining Discussion-Lathes, Mills, CNC.

Wow Dan!

Welcome to AF  Do you take orders?  j/k j/k

__________________

Guideline for happy modeling: Practice on scrap. Always try something new. Less is more. "I have a plan so cunning, you could put a tail on it and call it a weasel" - Edmund Blackadder |

|

|

|

|

|

#75 | |

|

AF Newbie

Join Date: Jun 2007

Location: northampton

Posts: 47

Thanks: 1

Thanked 0 Times in 0 Posts

|

Re: Machining Discussion-Lathes, Mills, CNC.

Reply to Klutz 100 I will be taking orders

Asking any Mods, can this thread be posted into the machining forum Thanks Freakray Last edited by PlutoniumDan; 11-10-2007 at 07:14 PM. |

|

|

|

|

|

POST REPLY TO THIS THREAD |

|

|

|