I guess you'll lost 10 minutes after the "print launch" if you work at the sloth speed

So we have 50 min. left: more than needed

I guess we deserve a good beer before the etching

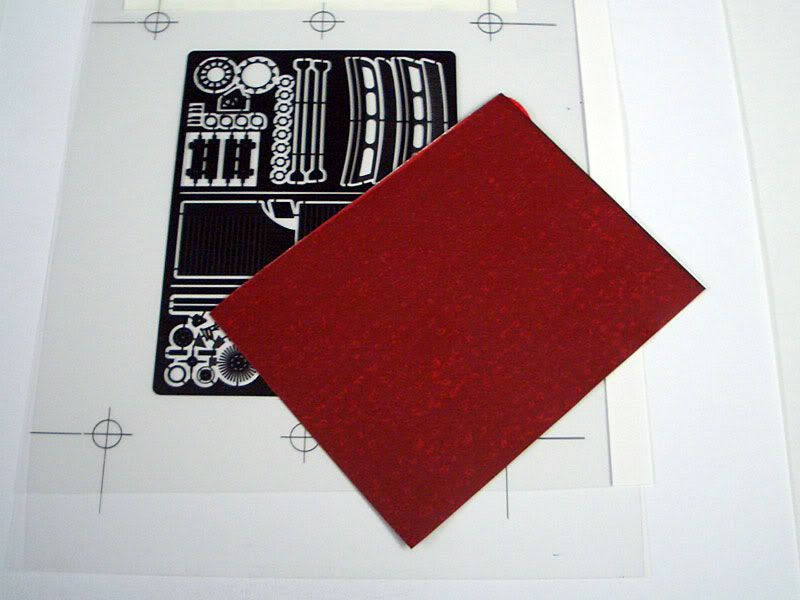

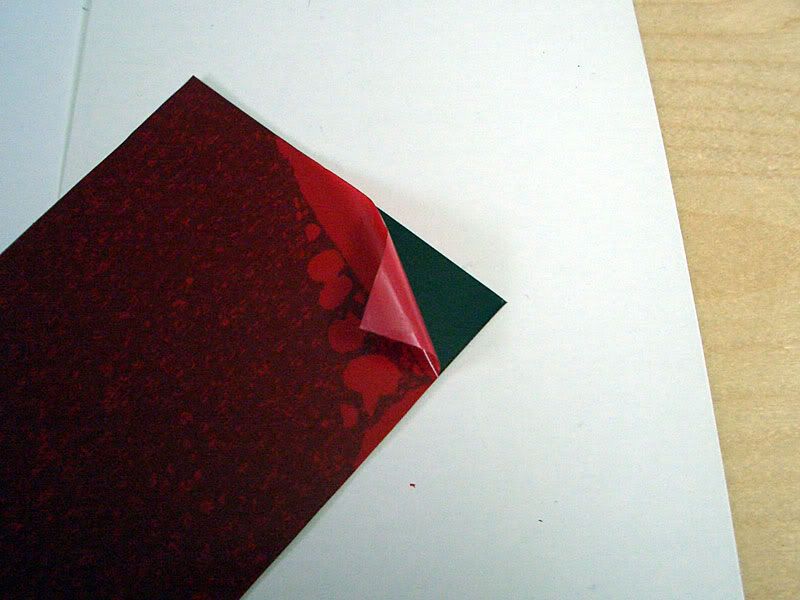

Time to cut th plate in the desired size (do it with a sharp knife since scissor could bend it) and peel the protection tape: you'll do it quickly at daylight, be sure to avoid overexpositions.

Insert the plated (peeled LOL) in the "pocket" you done with slides, fix it with tape and expose it in the UV device. Normally it need 2-3 minutes each side. I done a kind set-up on my UV device pulling tall the glass board approx 10-12 cm over lams: it help me a smooth and costant exposition, so times are a bit longer: approx 6 min/side. Also with old developer you may help chemicals with 2-3 mins more of exposition.

So other 12 mins, 38 left, we have to start run

(just in case you want ask: my device isn't do by paper LOL I just filled with cardboard to avoid UV rays go around LOL)

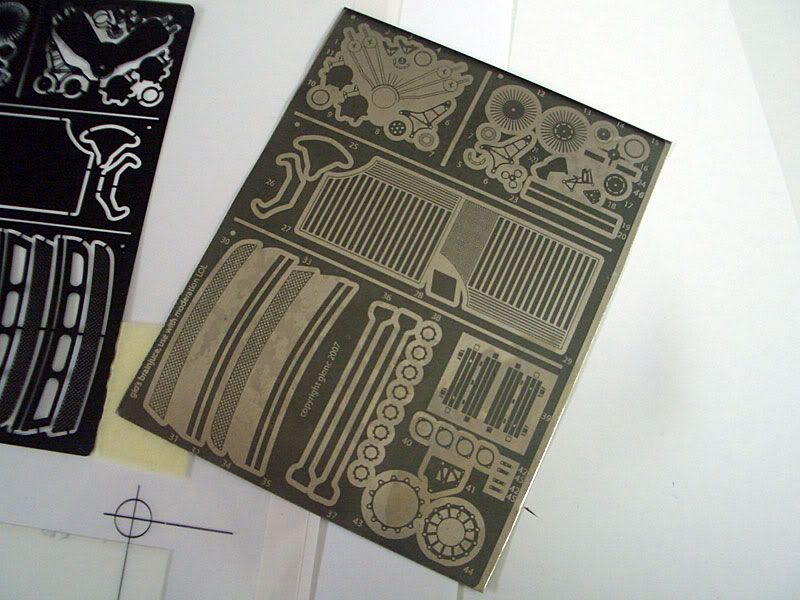

Develop the board: it would take a couple mins for side with 20° warm solution, this is teh result:

Like you'll see holes are now bare metal and stuff we need to keep are protected by a gray/green/blue laquer.

33 mins left: time to etch.

Etching solution I used need to be warmed at approx 45° (I believe) and need to be stirred often. Or you buy a etching station with pump and warmer or...

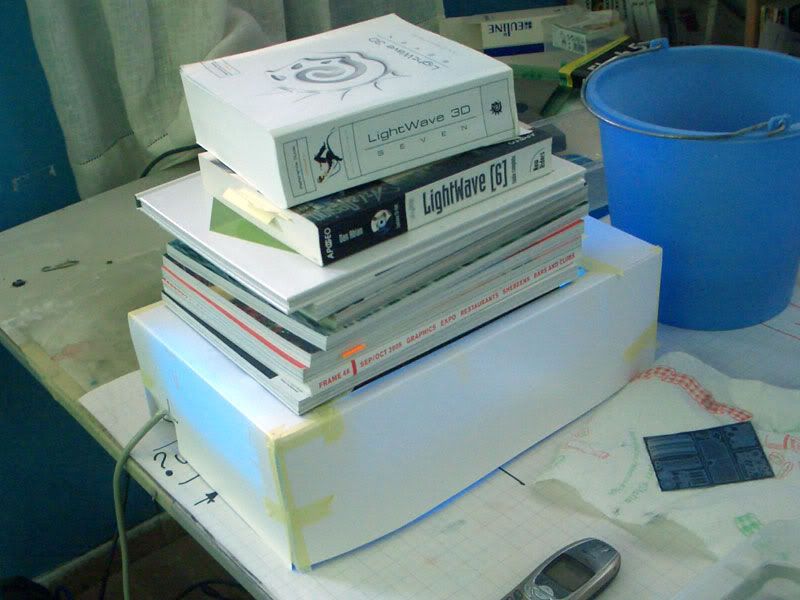

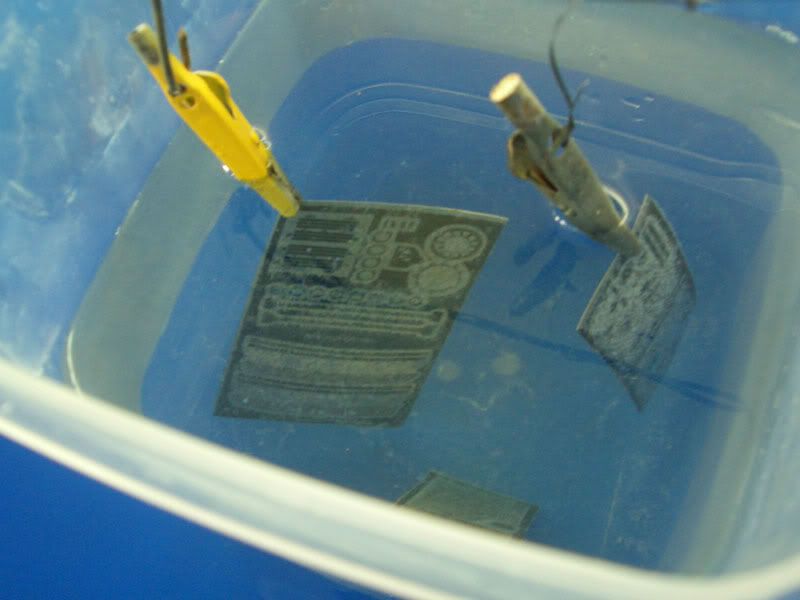

I put warm water in the big blue container, later the chemical reaction help to keep the temperature HI, may be useful cut your board in several parts, etching times may be different:

I found this solution to keep parts:

despite at begin acid is transparent, it quickly become cloudy: look what happened: it eat me a new pincher in few minutes! May be was a strange material, old two dirty pinchers are ok!

Every so often mix the solution, stirring it with a plastic wand and check it: you'll see that acid start to eat

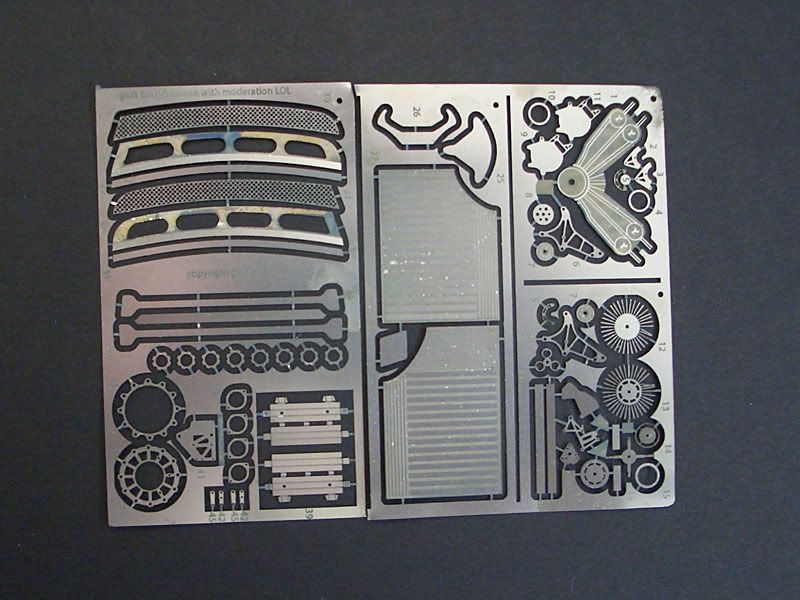

Finally after 20-25 (30/40 with 3-4 times used acid) is time to wash your etched plate under water, dry it and wash on solvent to clean from the laquer:

After cleaning, this is the result (1h later

THE END!

THE END!

thanks a lot guys for read it, sorry if something was unclear (also for shi##y english) and be free to ask, if I can I'll answer.

ciao

gio