Hello again,

Firstly, I can confirm that there is no hidden message behind the...'All-Black'...colouring of the jig! I sorted all my bricks by colour several years ago and I just happen to have more black Technic stuff than any other...and trying to make it in red white and blue 'Martini' colours would have been a step too far!

Anyway, back to the 935. The last layer of fibreglass on the bonnet refused to harden, so I wasn't able to remove it from the mould until returning home from Oulton Park at the weekend. I think the problem was that I usually mix up a set amount of resin and hardener in the 3:2 ratio, and that's enough for several layers on two or three moulds. When I laid the last layer on the bonnet, I mixed up a much smaller quantity of resin to avoid excessive wastage, but couldn't have added enough hardener. Grr!

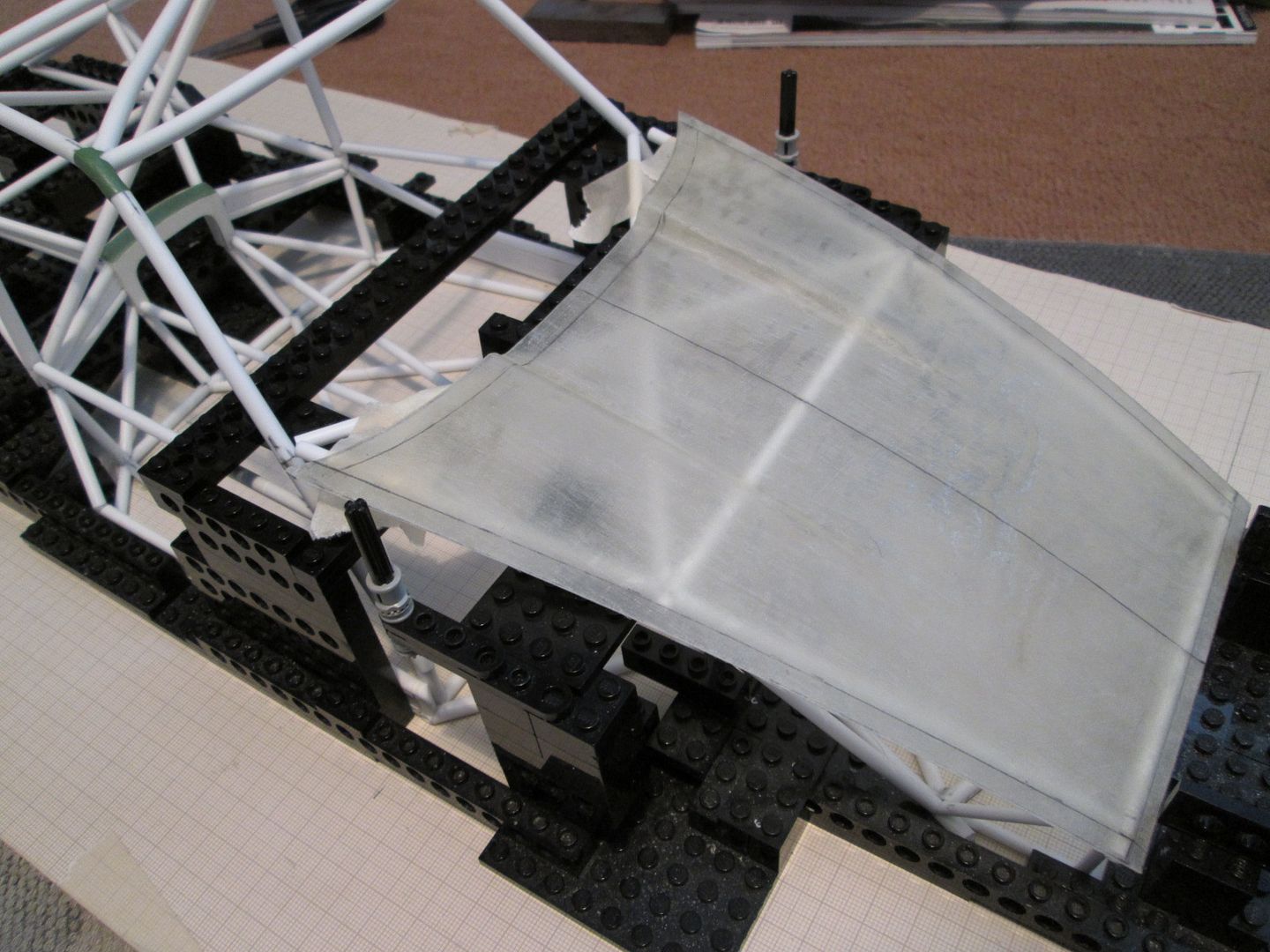

Still, once it was prised off the mould and cleaned up, I was pleased with the result:

I've not trimmed it to the exact shape just yet, but it's close enough to work with for the next stage. It will need some internal reinforcement eventually, but not while I still might need to put it back on the mould.

Before I could make the pattern for the ridge which runs around the base of the windscreen I had to work out where the chassis tubes were going to be. You can see these in the last photo, and again here:

I didn't want to glue these in place just yet, so more lego has been added to hold them in position while I sort out the bonnet. The thing I can't understand about the original Porsche frame is why they didn't continue the outermost top rails up to the main roof pillars (unlike on my frame right now). The Freisinger photos clearly show these tubes cut short once they have been bolted through the inner wheel-arch pressings - they don't run up to the pillars. The

diagonal cross-bracing connects to the pillars, but not the outers. I assume that it was due to the way they assembled the modified 911 shell over and around the tube frame - perhaps there was no way to fit it with the tubes running through. It would make

my life easier to connect these tubes to the roof pillars, but in the interests of accuracy, they'll be cut short before final fitment!

So, after getting the frame in place, I spent a long time measuring, checking, and working out how I was going to get the new mould made. I recycled a few foam pieces from when I made the main roof mould, added some cardboard, and this was the end result:

A seam of greenstuff was added to create the transition between the two surfaces, and was given a final smoothing tonight:

This mould is now ready to start fibreglassing! Trouble is, I now want to get some other moulds ready so I can lay-up several panels at once. I made a list last week of all the moulds required for this project - it's currently up to thirty-six! It's certainly the most fibreglass-intensive project I've done, and I apologise that there hasn't been much 'styrene action' going on so far - but I really want to get the fibreglass to the right stage before we get into Autumn and the weather turns cold (yeah, I know - it's been a lousy summer here in the UK...) Then I can spend the cold, dark winter evenings working on the engine, gearbox, etc. That's the plan, anyway!

So, I'm now busy trying to get a couple more moulds ready for laying-up over the weekend - I think it will be the mk2 sill panels, although I keep thinking about the inner doorskins too. Hopefully you'll see some progress on Sunday.

Have a good week,

SB