Quote:

|

Originally Posted by Plasticmodeler702

Thank you soo much!! What sizes do you use?

|

I eyeball it. I just get a bunch of diameters at the store, bring them home, and go from there. The largest in the following tutorial is 5/32 OD, telescoping down from there (1/8 OD, and 3/32 OD).

To make an exhaust similar to the one on my Honda Fit, you can use 3 diameters of tubing, like mentioned above. The smallest tubing in the Fit's case is brass, not aluminum, to match the orange on the car.

The materials you need are shown here. The tubing, a mitre box, a saw, super glue, hobby knife, and some polishing pads to finish the piece.

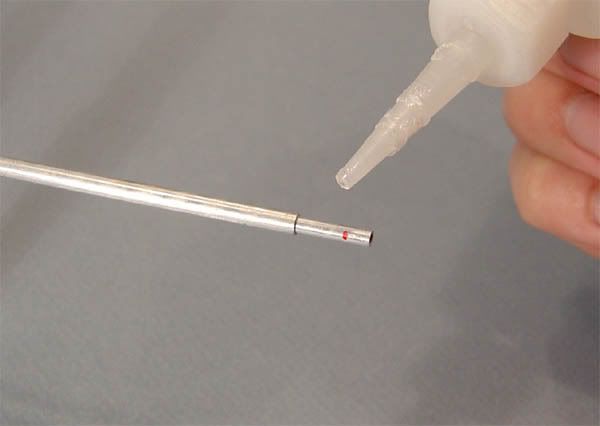

The first thing I do is mark the smallest diameter about 3" scale down from one end. You can eyeball this part, too, if you wish. This will be the exhaust tip. I then put a drop of glue on the side of the mark AWAY from the tip, and usually put it 1-2mm away from the mark. I then slide the next size up of telescoping tubing over the smallest, and as I approach the glue and the mark, I twist the tubes in opposite directions to spread the glue and ensure a better bond. I slide the tube only to the mark I made earlier (or just past it, to hide the mark).

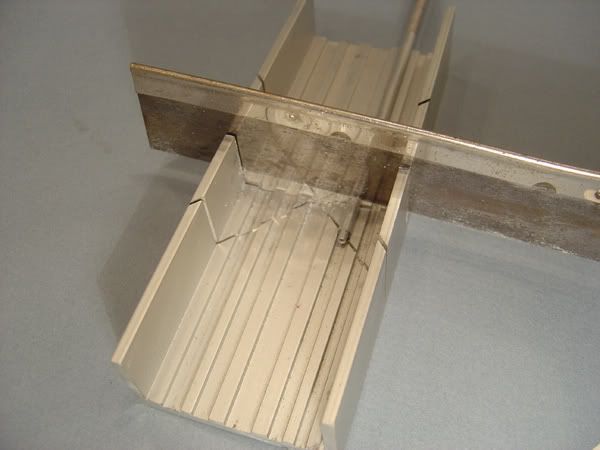

I like to chamfer the largest diameter tubing on the inside, to replicate the look of the metal skin wrapped around the disk that makes the end of the muffler. I do this by running my hobby knife's blade around the inside of the tubing, and removing just a sliver of metal from the inside edge.

I then glue the largest tubing over the middle sized tubing, just as I did the middle over the smallest, but pushing the largest to the end of the middle. This builds up the layers of the tubing, and gives more depth and greater... erm... detail to the part.

You can repeat this step to get an even bigger canister with a relatively smaller tip. Don't chamfer the two middle sizes, just the outer one. I then make my first and only cut with the mitre box. I place the whole assembly in a snug groove in my mitre box and cut about a scale foot off. The layers of tubing strengthen them and keep them from crushing, but I still use light even strokes to slowly cut through the soft aluminum.

The result is a fairly convincing muffler. Chamfer the smallest diameter tube in the tip, and put a touch of flat black paint on the inside, and you will hide the overscale thickness of the tube. You can detail this up with carbon fiber decals, rivets, more layers, whatever, to get the effect you want. You can even bend the smallest tube slash cut it for different styles.